- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Video Examples of our Projects

Example 1.

Thin

wall Disposable Rectangular 750ml Tub

2 Cavity Mold

Part weight: 22.5 grams

Wall thickness: 0.55mm (0.022 inch)

Material: PP homopolymer

Cycle time: 4.1 seconds (free drop)

Valve gate hot runner

Annual production capability: 14 million (2 cavities)

Machine clamp requirement: 260T

Example 2.

Thin wall Disposable Rectangular 750ml Tub

2+2 Stackmold

Part weight: 22.5 grams

Wall thickness: 0.55mm (0.022 inch)

Material: PP homopolymer

Cycle time: 6.6 seconds (robot takeout)

Hot tip hot runner

Annual production capability: 17.5 million (4 cavities)

Machine clamp requirement: 300T

Example 3.

Thin

wall Disposable Rectangular Lid

2+2 Stackmold

Part weight: 12.4 grams

Wall thickness: 0.51mm (0.02 inch)

Material: PP homopolymer

Cycle time: 3.7 seconds (free drop)

Hot tip hot runner

Annual production capability: 30 million (4 cavities)

Machine clamp requirement: 250T

Example 4.

Thin wall Disposable Rectangular Lid

4+4 Stackmold

Part weight: 12.4 grams

Wall thickness: 0.51mm (0.02 inch)

Material: PP homopolymer

Cycle time: 5.5 seconds (robot takeout)

Hot tip hot runner

Annual production capability: 42 million (8 cavities)

Machine clamp requirement: 500T

Click here to learn more about Thin Wall Moulding

Example 5.

Rectangular Lid for 5 litre Storage Tub

Part weight: 102 grams

Material: LLDPE

Cycle time: 9.7 seconds on a packaging machine (14-16 seconds on general purpose machine)

Annual production capability: 2.8 million @ 9.7 seconds

Machine clamp requirement: 120T

Example 6.

5 Litre Storage Tub

Part weight: 218 grams

Wall thickness: 1.3 mm (0.0512 inch)

Material: PP random copolymer

Cycle time: 11 seconds (on packaging machine, 18-20 seconds on general purpose machine)

Annual production capability: 2.6 million @ 11 seconds

Machine clamp requirement: 180T

Example 7.

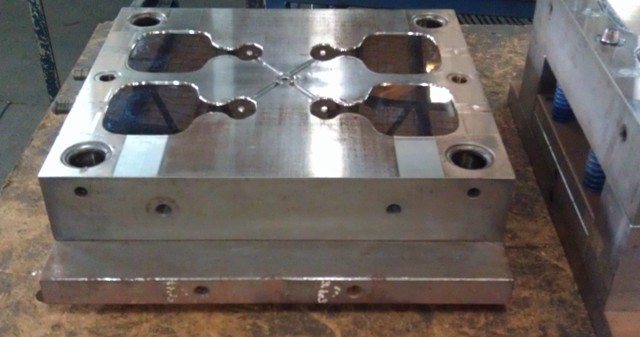

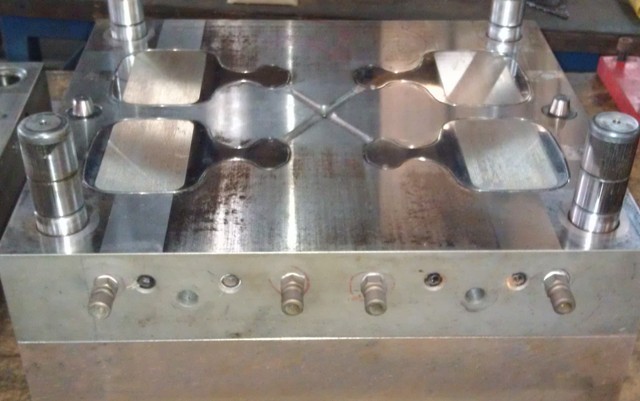

4 cavity 2 plate Mold

Part weight: 25 grams

Material: Polycarbonate

Cold runner mold

Cycle time: 13 seconds

Annual production capability: 8.7 million

Machine clamp requirement: 120T

Example 8.

Chinese Liquor 3 Piece Cap

16

cavity collapsing core mold

Part weight: 4.8 grams

Material: K-Resin

Cycle time: 13.7 seconds

Hot tip hot runner

Annual production capability: 33 million

Machine clamp requirement : 150T