- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Plastic Injection Molding Process - Energy Saving Techniques

The plastic injection molding process can start saving you money immediately.

I am about to show you how to use the molding process more efficiently.

An important part of the plastic injection molding process are the process parameter settings such as hold time and screw plasticizing time. Process parameters give direct control over part quality and cycle time. Click here to read about how plastic drying also influences part quality.

But they also have another function.

Process parameters can heavily influence the energy consumption of a molding machine.

By experimenting with process parameter settings you can potentially cut thousands of dollars a year off your energy bill.

A recent case study we performed on a 260 ton Sumitomo hydraulic injection moulding machine showed that the electrical energy cost per part was reduced by 23% just by changing molding process parameters. Click here to find out about another way of reducing costs by fixing flash quality problems.

And click here to find out how to save costs by eliminating short shot quality issues.

This result was achieved during a 6 hour production run. A small investment in time for such a large, ongoing return.

We want to help you get the same result by showing you how easy it is to do.

Plastic Injection Molding Process Case Study

Equipment used:

- 260T Hydraulic injection molding machine with single cavity mold

- Chiller unit

- An energy meter (see figure 1) Also called a watt meter

Procedure

Disconnected moulding machine from mains power via circuit breaker and then connected the energy meter to the machines power supply.

Once barrel heaters and hydraulic oil were up to temperature production commenced and continued for one hour before the first energy consumption readings started.

A photo of the part produced is in figure 2.

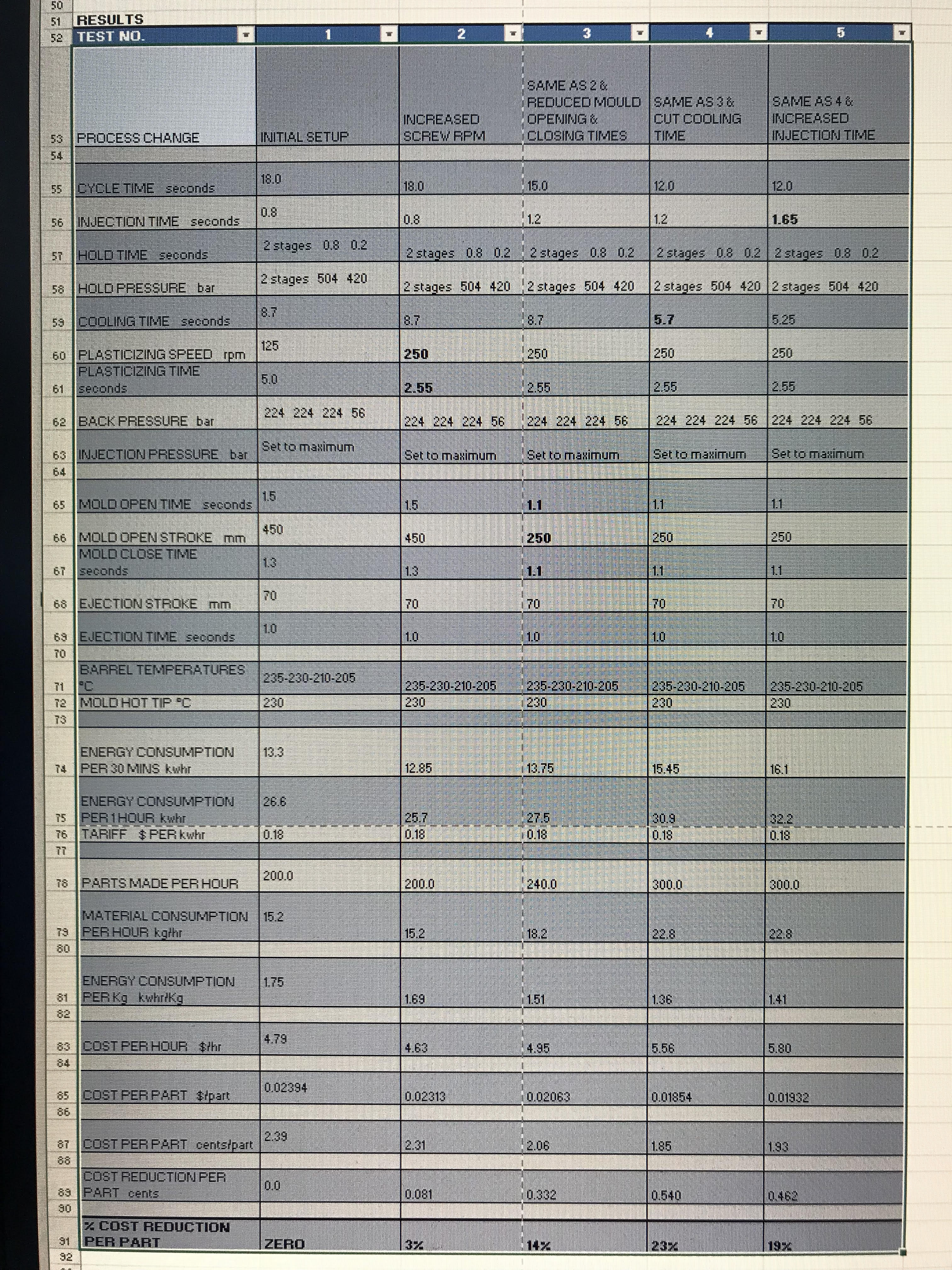

In the first test, the amount of energy consumed during a 30 minute period was measured with the original plastic injection molding process parameter settings.Cycle time was 18.0 seconds. See table 1 below for a list of all parameters.

The electricity cost per part was calculated to be 2.39 cents.

For the 2nd test we chose to double the RPM speed of the plasticizing screw. At the end of the 30 minute period we could see that this reduced energy consumption by 3.5% (without effecting quality) so the cost per part reduced to 2.31 cents. Cycle time remained at 18.0 seconds.

In test 3 cycle time was reduced by increasing the mould opening and closing speeds. Although the energy consumption slightly increased during the 30 minute time interval, the production quantity actually increased from 100 parts to 120 parts so the cost per part went down to 2.06 cents.

Test 4 was to cut cooling time by 3 seconds from 8.7 to 5.7 seconds and the cost per part reduced again to 1.85 cents. A 23% reduction in cost compared to test 1.

Test 5 involved increasing the fill time from 1.2 second to 1.65 seconds and reducing the cooling time so that the cycle time remained the same as test 4 at 12.0 seconds. The result was an increase in cost per part to 1.93 cents.

All these results are in Table 1 below.

Results

The results for this experiment show that for this particular machine producing this part, energy consumption was reduced by up to 23% from the original settings. This translates directly into a 23% saving in electricity costs per part. And this was done just by changing some of the parameters in the plastic injection molding process.

If your annual electricity cost for this machine and part was $10,000 then that translates into a saving of $2,300 per year.

Imagine if all of your machines could have at least a 10% reduction in cost then this would mean tens of thousands of dollars in savings per year. That's capital that can be used to grow your business.

More importantly, the results show that the machine uses energy more efficiently at faster cycle times. This is one benefit of fast cycling thin wall injection molding.

Click here to learn more about the benefits of thin wall injection molding.

In test 1 the kwhr per kg of polypropylene was 1.75 at a cycle of 18.0 seconds. In test 4 the kwhr per kg reduced to 1.36 at a cycle time of 12.0. So there is a double benefit of having the fastest cycle time possible: the most obvious is the increased production output but the hidden benefit is the reduced electricity cost. It is cheaper to make parts at faster cycle times with hydraulic machines.

Conclusion

The fact is, it easy for an injection molder to reduce electricity costs on existing hydraulic machines just by adjusting parameters in the plastic injection molding process.

The ability to reduce costs without having to invest in expensive new technology machines is totally in your control.