- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

For Sale

Proven Injection Mold Designs for Thin Wall Food Packaging Parts

Available for immediate download!

Buy today, start manufacturing tomorrow!

Injection Mold Design Example

Injection Mold Design ExampleCURRENT MOULD DESIGNS FOR SALE: scroll down for details

A-500ml Round Disposable Food Tub 1 Cavity

NEW_A2-500ML Round Disposable Food Tub 2 Cavity

CURRENTLY DISCOUNTED

B-500ml Round Disposable Food Tub 4 Cavity

B2-250ml Round Disposable Tub 2 Cavity

NEW_B3-250ml IML Round disposable Tub 2 Cavity Mould

C-Common Round Disposable Lid 1 Cavity

C2-Common Round Disposable Lid 2 Cavity CURRENTLY DISCOUNTED

D-Common Round Disposable Lid 4 Cavity

E-1000ml Rectangular Disposable Tub 1 cavity CURRENTLY DISCOUNTED

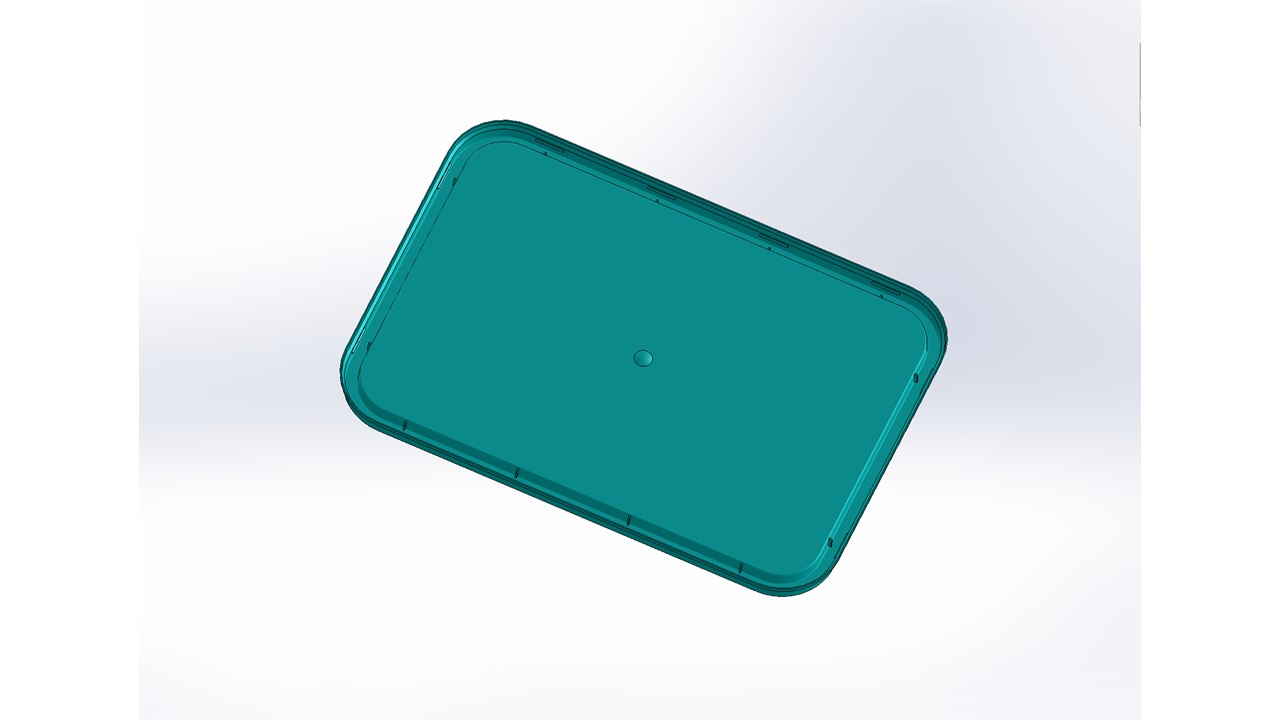

F-Rectangular Disposable Food Lid 1 cavity (to suit 1000ml tub) CURRENTLY DISCOUNTED

G- 500ml Rectangular Disposable Food Tub 2 Cavity

G2-750ml Rectangular Disposable Food Tub 2 Cavity

H-Rectangular Disposable Food Lid 4 Cavity (to suit 2 cavity 500ml tub)

I-Rectangular Disposable Food Lid 2+2 Stack Mould Design (to suit 2 cavity 500ml tub) Currently Discounted

K-2 Litre Rectangular Ice Cream Tub 1 Cavity

All Mold Designs Include:

• full 3D assembly drawing of a proven mold design

• 3D drawing of each mold component including the plastic part

• full cooling system design for quick cycle time

• material selection guide pdf for mold plates & inserts

• mold maintenance procedure checklist

• tapered interlocks for robust alignment between fixed & moving side to maintain even wall thickness (this is a primary consideration when molding thin wall parts)

• both primary & secondary venting requirements to ensure part quality

• design for manufacture principles which ensures molds are easy to make

• design for easy maintenance

• support available via email and telephone (chargeable)

Why Would You Want to Buy?

With these 3D designs drawings, you can:

- request for wall thickness change free of charge to suit your target part weight

• use them as a training reference for your own tool design development (for toolmakers, design engineers, injection molders & educational organisations)

• add your own part design for reduced mold design, machining & commissioning time

• machine each component directly from the 3D drawing model

• modify the mold size or any other component drawing to suit your own needs

I made moulds for thin wall packaging parts for over 20 years at SK Engineering. During this time, I learnt to take a different approach to mold making compared to making molds for parts with thicker walls & slower cycle times. If I didn’t change, I would not have succeeded.

Most importantly, these designs will save you so much time and money. Designing & building these moulds take years to master. You will avoid making the mistakes that I made in the beginning.

The mould designs can be modified to suit your needs such as a different part design, moulding machine, In Mould Labeling (IML) or hot runner requirements

If you have a question before purchasing then click here contact us or continue reading to see details of the first mold design for sale.

If you require a mould design urgently that is not currently listed then contact us via our Mold Design Services page for a quote using your part drawing.

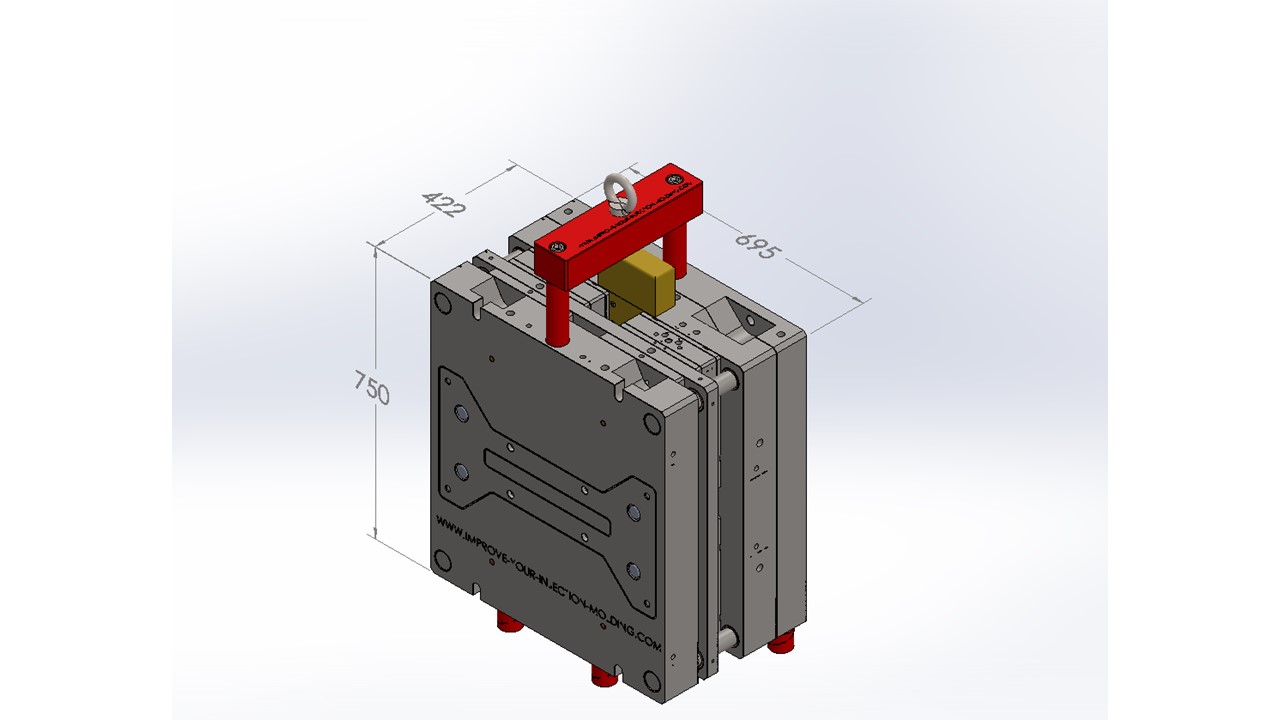

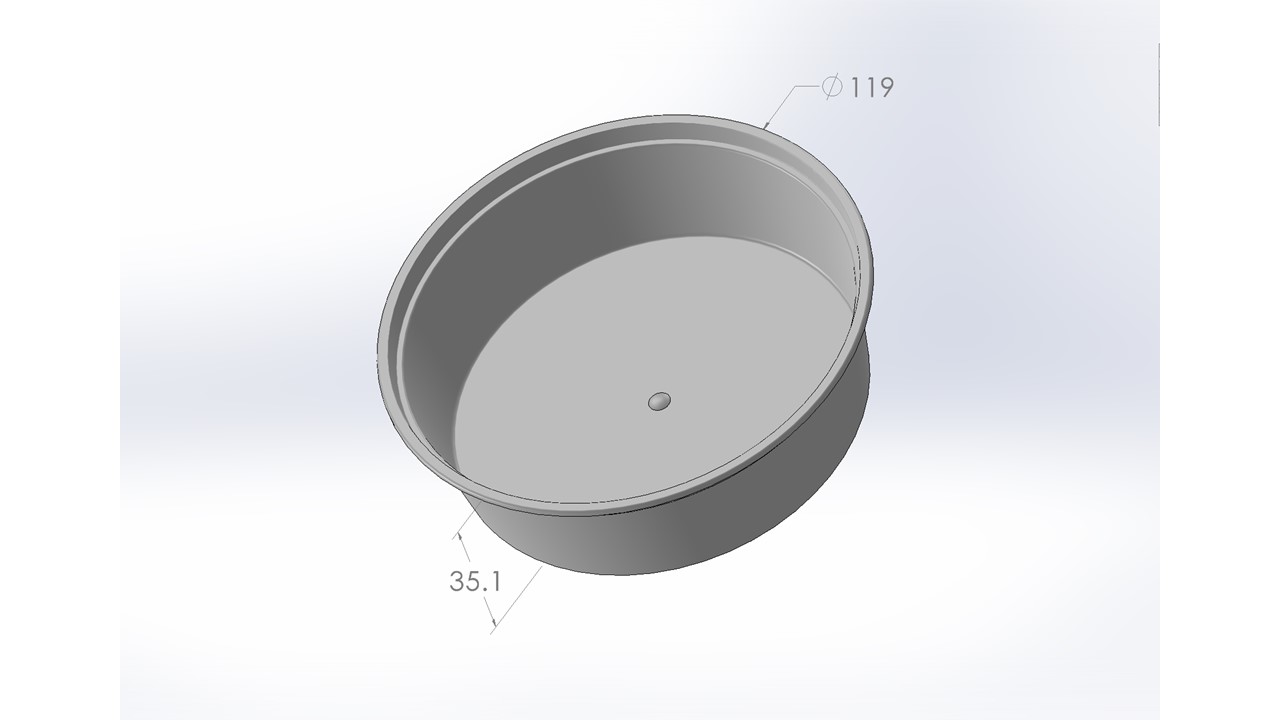

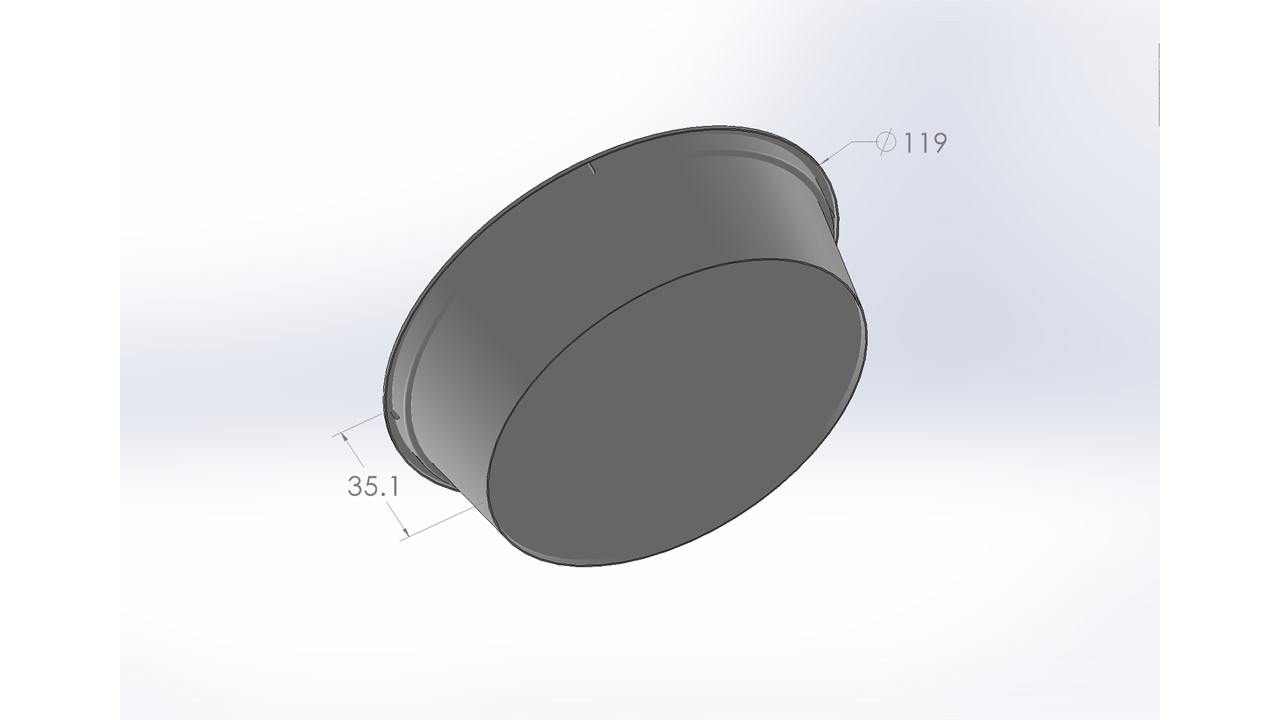

Design A

FOR SALE

Single Cavity Mold Design for the

500ml Round Disposable Food Tub

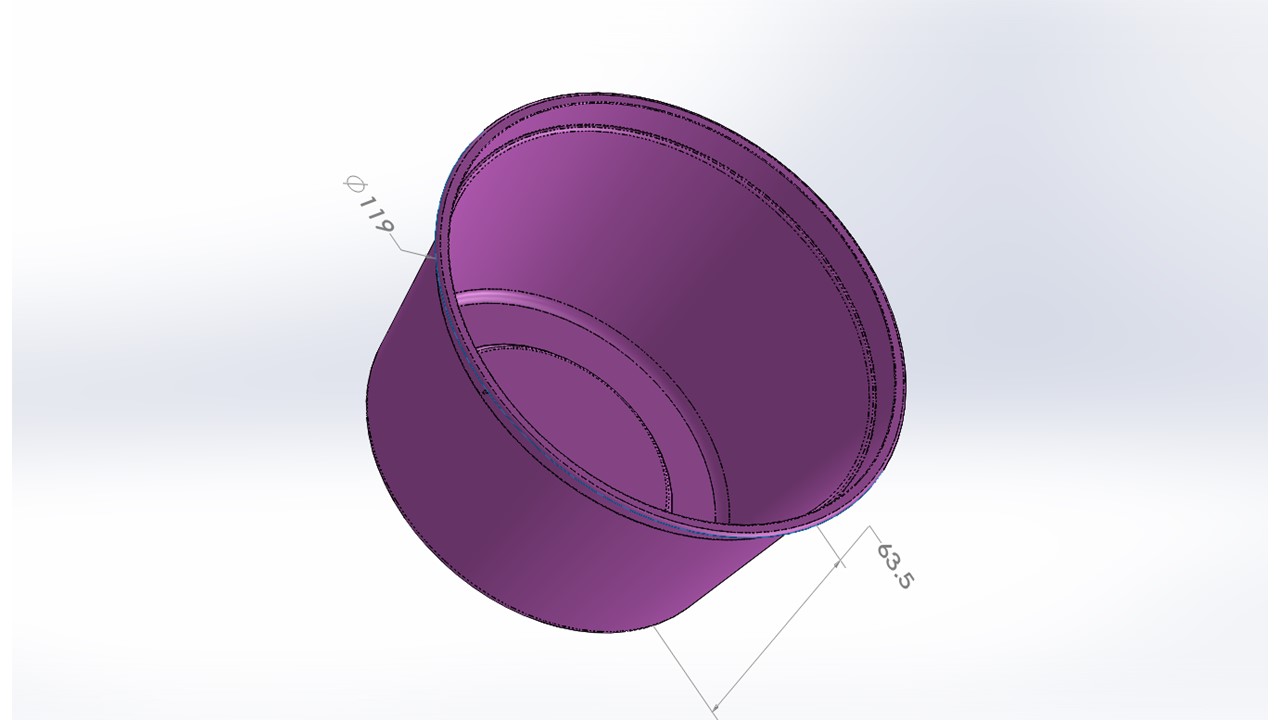

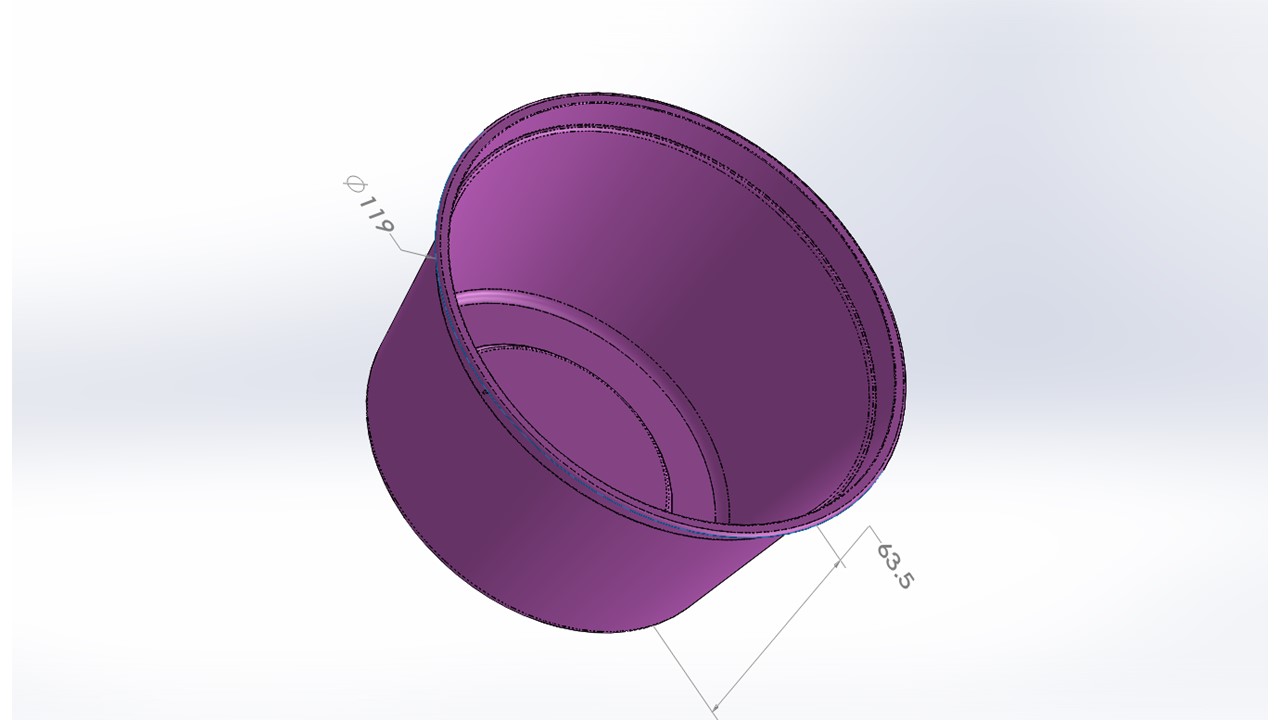

500ml Thinwall Disposable Food Tub

500ml Thinwall Disposable Food Tub 500ml Tub Mold Design For Sale

500ml Tub Mold Design For SaleDetails

Weight 13.1 Grams

Wall thickness 0.50mm or less. Nominate your wall thickness, for example 0.40mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 3.5-4.0 seconds (free drop)

Mould designed for 60 ton Sumitomo Demag high speed moulding machine OR similar

Annual product capability: 7 million (Based on 23hrs/day)

Mold designed with:

1. In House Hot Tip Hot Runner System(can be made by you)

2. Simple assembly techniques

3. Easy mold maintenance procedures

Click the PayPal link to purchase & download the complete SINGLE CAVITY 500ml Round Food Tub MOLD DESIGN in Parasolid and STEP format for just US$299

Design A2 -NEW

FOR SALE

2 Cavity Mold Design for the

500ml Round Disposable Food Tub

Currently Discounted

Details

Weight 13.1 Grams or less

Wall thickness 0.50mm or less. Nominate your wall thickness, for example 0.40mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 3.8-4.3 seconds (free drop)

Mould designed for high speed moulding machine

Mold designed with:

1. In House Hot Tip Hot Runner System (can be made by you)

2. Simple assembly techniques

3. Easy mold maintenance procedures

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 2 CAVITY 500ml Round Food Tub MOLD DESIGN in STEP format for just US$40

Note: downloaded files password locked so contact me to get password after payment.

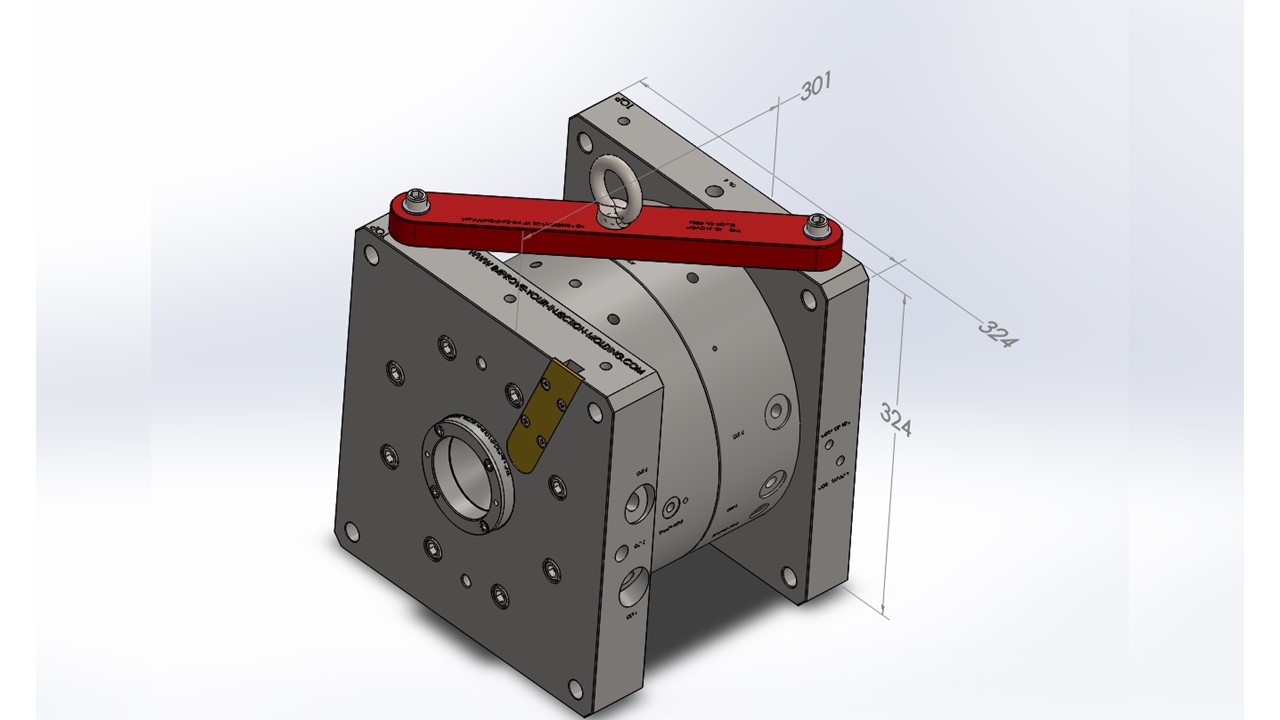

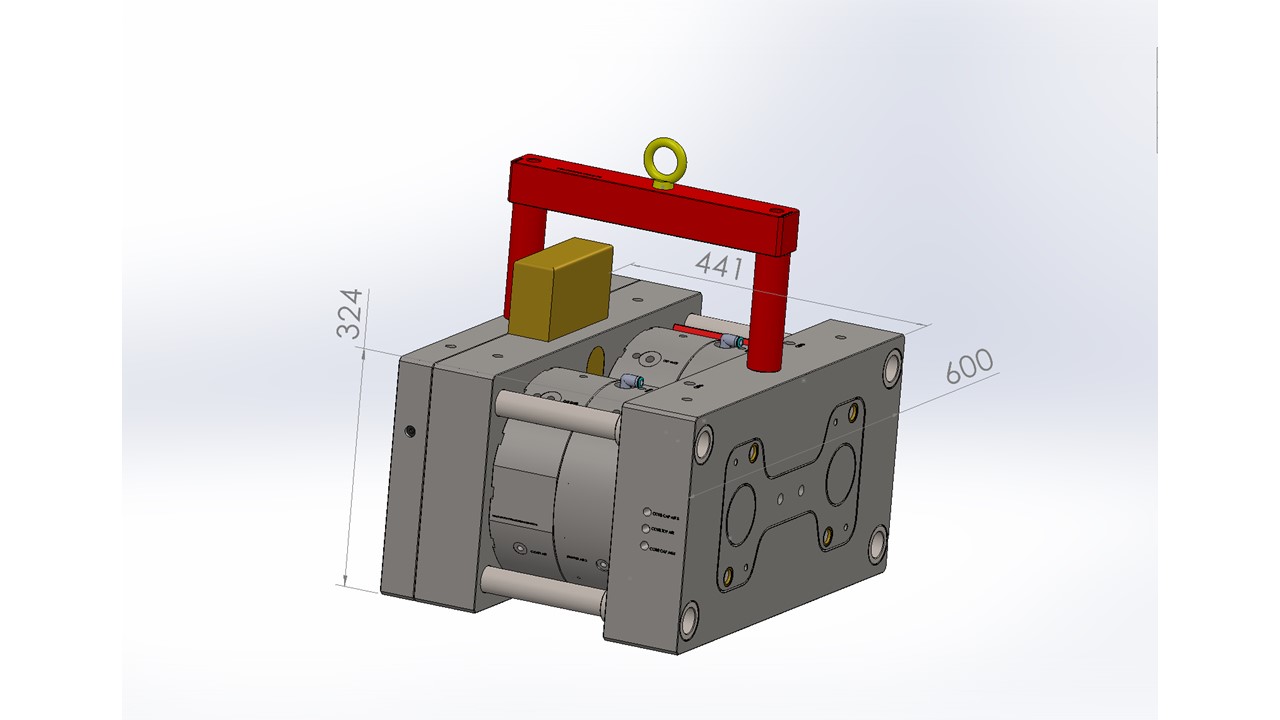

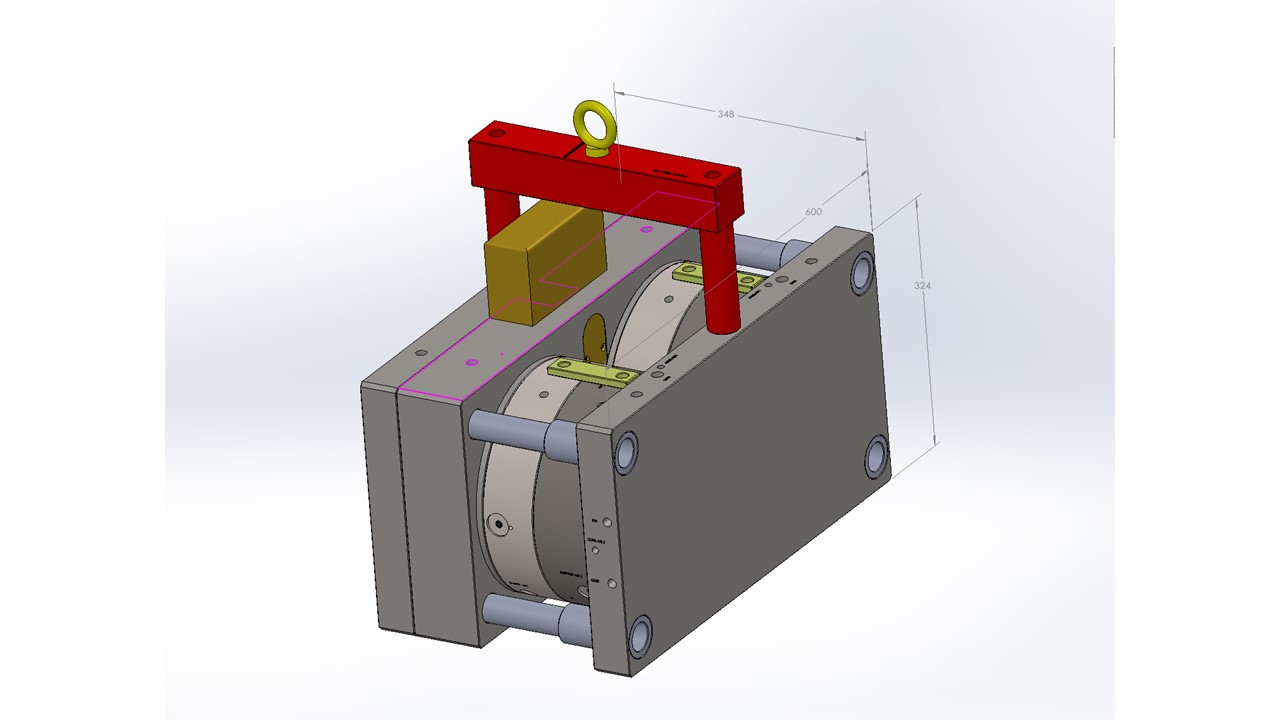

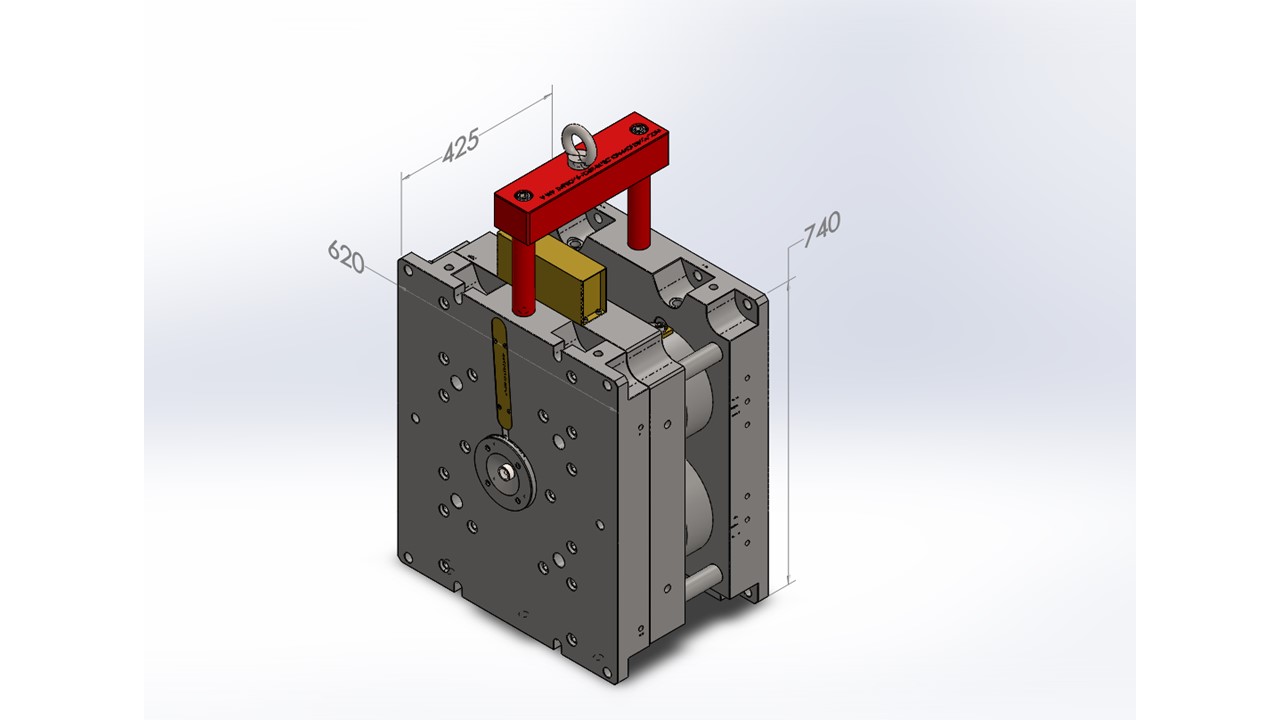

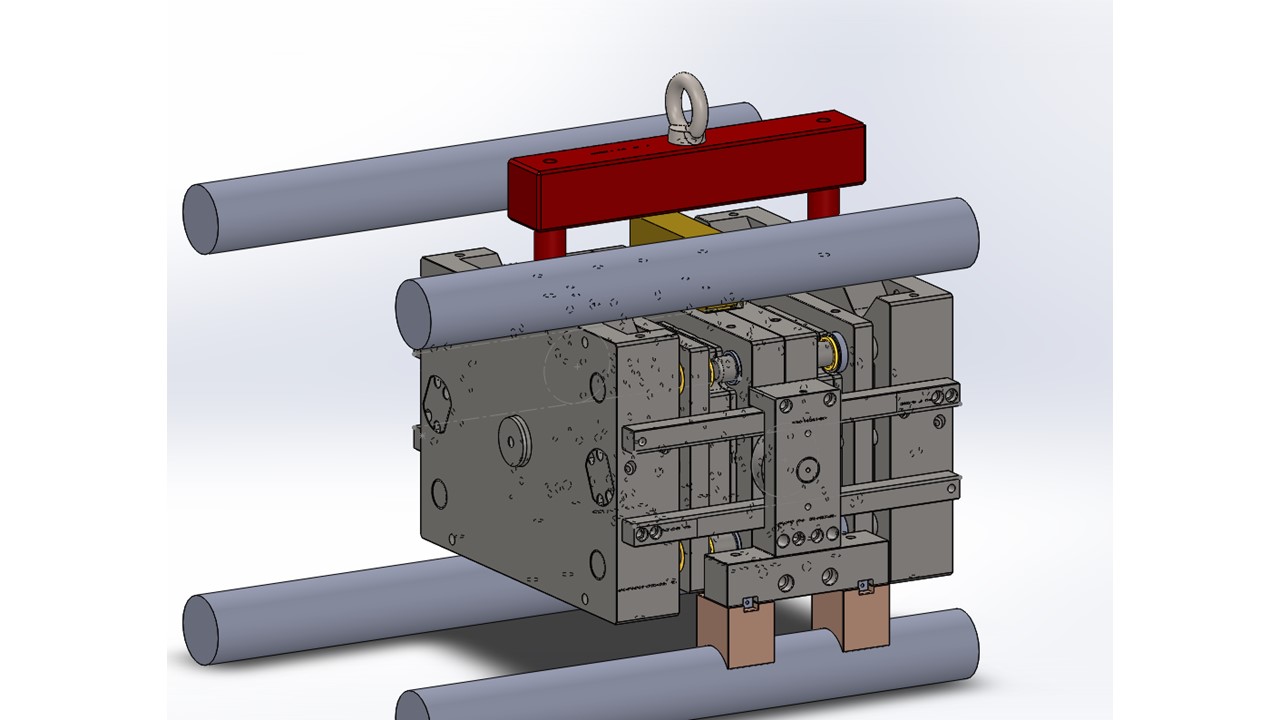

Design B

FOR SALE

4 Cavity Mold Design for the

500ml Round Disposable Food Tub

500ml Thinwall Disposable Food Tub

500ml Thinwall Disposable Food Tub 4 Cavity Tub Mold Design For Sale

4 Cavity Tub Mold Design For SaleThe 4 Cavity Mold in Production

4.0 seconds

Details

Weight 13.1 Grams

Wall thickness 0.50mm or less. Nominate your wall thickness, for example 0.45mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 4.0-4.5 seconds (free drop)

Mould designed for 280 ton Sumitomo Demag high speed moulding machine

Annual product capability: 26 million (Based on 23hrs/day)

Mold designed with:

1. In House Hot Tip Hot Runner System (can be made by you)

2. Simple assembly techniques

3. Easy mold maintenance procedures

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 4 CAVITY 500ml Round Food Tub MOLD DESIGN in STEP format available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.

Design B2

FOR SALE

2 Cavity Mold Design for the

250ml Round Disposable Food Tub

6.9 GRAMS

6.9 GRAMS

2 cavity mould in production based upon the 250ml mould design.

Testimonial

Thanks a lot we have purchased a thinwall mould design from you, and it is very helpful for our development of thinwall mould

Synergy Plast India

Details

Weight 7.2 Grams

Wall thickness 0.40mm or less. Nominate your wall thickness, for example 0.38mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 2.5-3.0 seconds (free drop)

Mould designed for high speed packaging machine

Annual product capability: 20 million (Based on 23hrs/day)

Mold designed with:

1. In House Hot Tip Hot Runner System (can be made by you)

2. Simple assembly techniques

3. Easy mold maintenance procedures

4. No ejector plate (air ejection only)

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 2 CAVITY 250ml Round Food Tub MOLD DESIGN in STEP format for just US$299.

NEW

Design B3

FOR SALE

With In Mold Labelling compatibility

2 Cavity IML Mold Design for the

250ml Round Disposable Food Tub

250ml Tub with IML foot

250ml Tub with IML foot 250ml Tub with IML foot

250ml Tub with IML foot 2 cavity mould with In Mold Label Compatibility

2 cavity mould with In Mold Label CompatibilityWeight 8.1 Grams

Wall thickness 0.40mm or less. Nominate your wall thickness, for example 0.38mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 2.5-3.0 seconds (free drop)

Mould designed for high speed packaging machine

Annual product capability: 20 million (Based on 23hrs/day)

Mold designed with moving ejector plate

Note: mould requires valve gate hot runner. Yudo, Husky or Mold Masters hot runner recommended. Cavity gated. Cavity pitch 284mm.

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 2 CAVITY 250ml Round Food Tub MOLD DESIGN with IML compatibility in STEP format for just US$460.

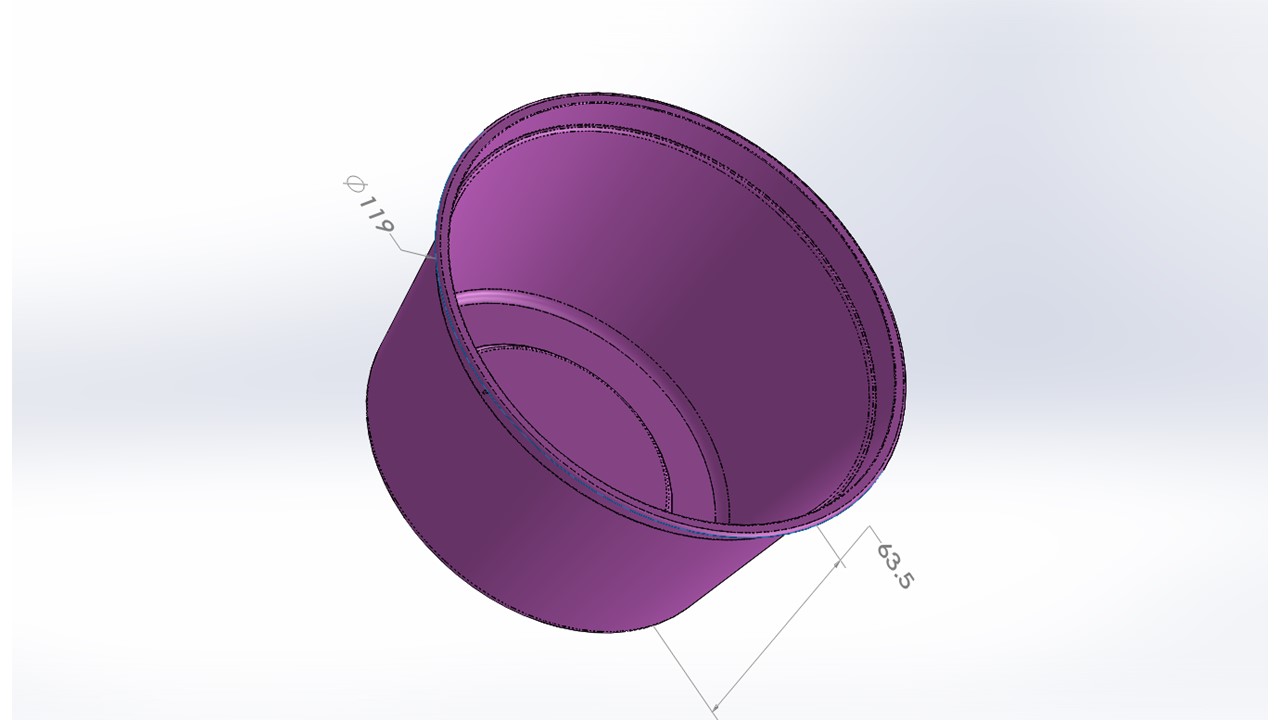

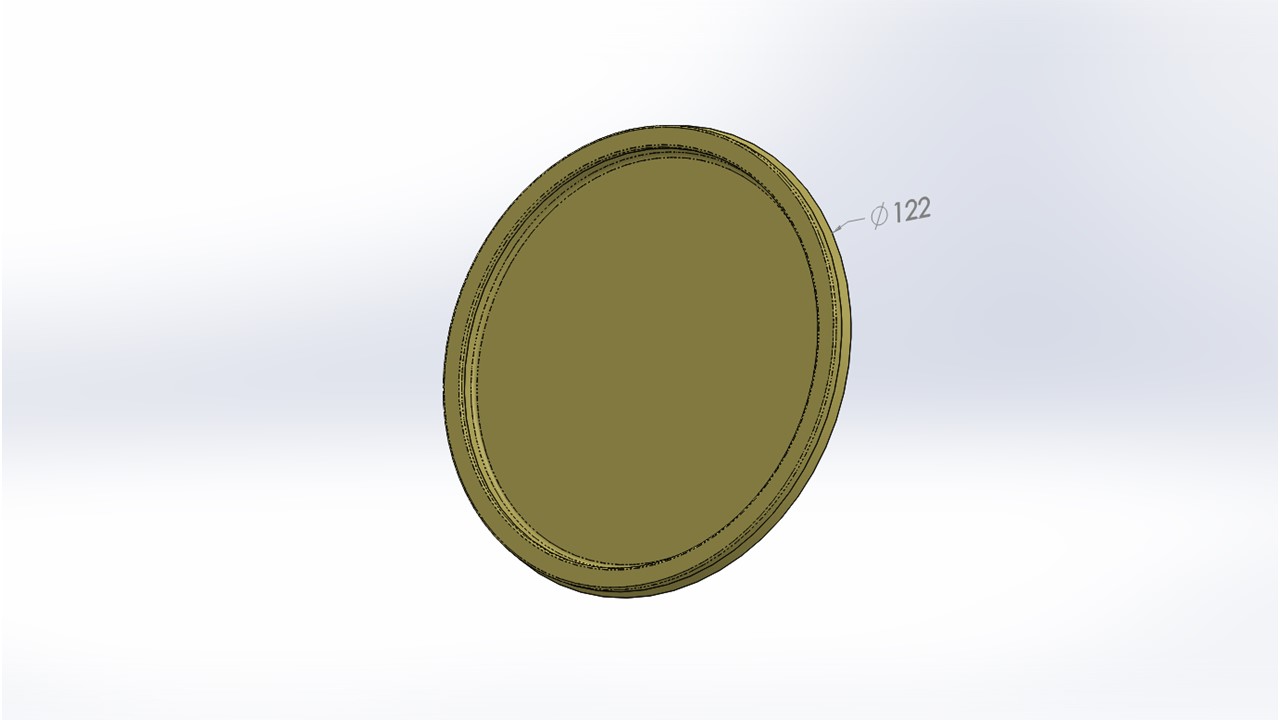

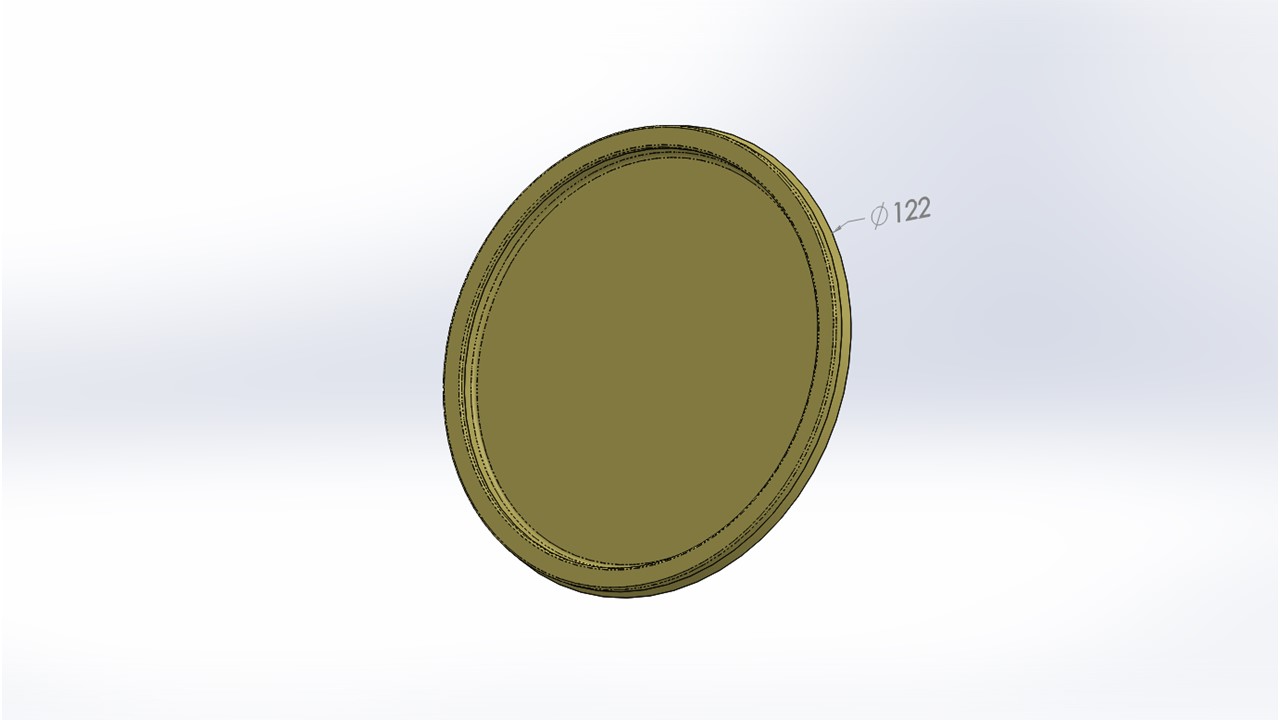

Design C

FOR SALE

Single Cavity Mold Design for the

Common Round Disposable Lid

Common Round Disposable Lid

Common Round Disposable Lid

Details

Lid suits 500 round tub

Weight 6.3 Grams

Wall thickness 0.45mm or less. Nominate your wall thickness, for example 0.38mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 3.0-3.5 seconds (free drop)

Mould designed for 60 ton Sumitomo Demag high speed moulding machine OR similar

Annual product capability: 9 million (Based on 23hrs/day)

Mold designed with:

1. In House Hot Tip Hot Runner System(can be made by you)

2. Simple assembly techniques

3. Easy mold maintenance procedures

Buy Now

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete SINGLE CAVITY Common Round Lid Tub MOLD DESIGN in STEP format for just US$285 available for immediate download.

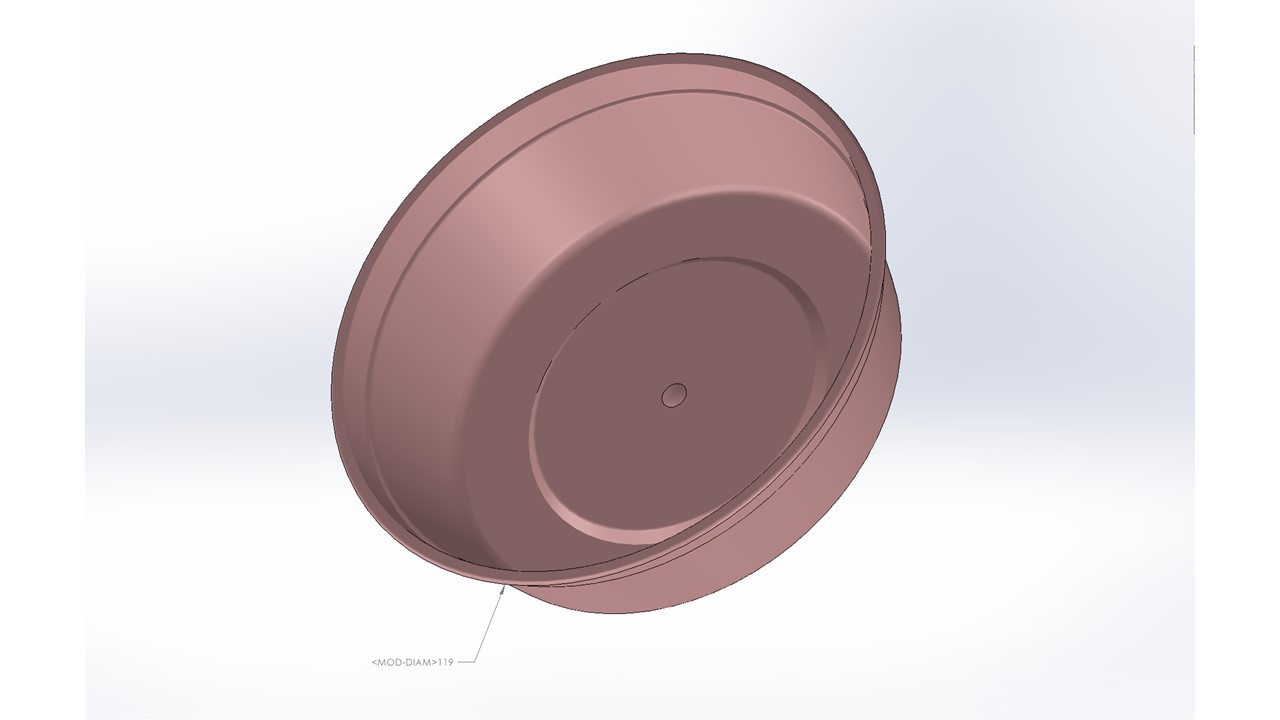

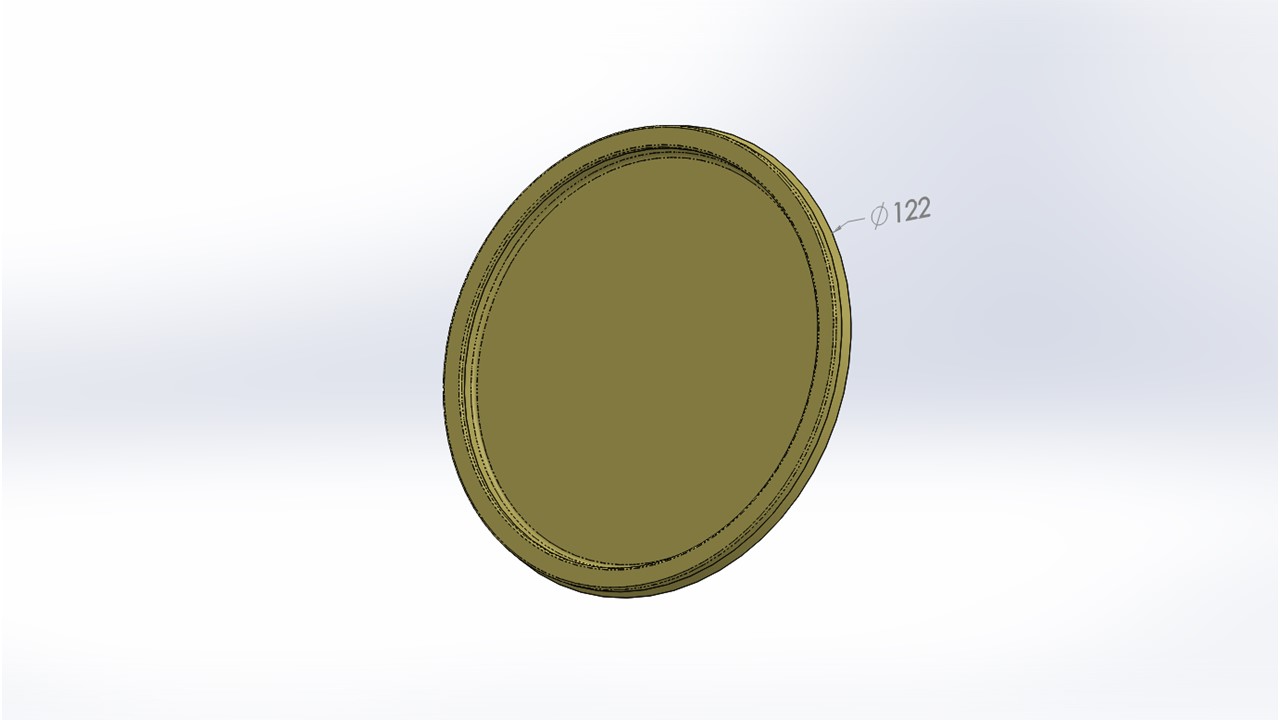

Design C2

FOR SALE

2 Cavity Mold Design for the

Common Round Disposable Lid

Currently Discounted

Common Round Disposable Lid

Common Round Disposable Lid 2 CAVITY ROUND LID

2 CAVITY ROUND LIDDetails

Lid suits 250&500 round tubs

Weight 5.8 Grams

Wall thickness 0.40mm or less. Nominate your wall thickness, for example 0.38mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 2.0-2.5 seconds (free drop)

Mould designed for high speed moulding machine

Mold designed with:

1. In House Hot Tip Hot Runner System(can be made by you)

2. Simple assembly techniques

3. Easy mold maintenance procedures

Buy Now

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 2 CAVITY Common Round Lid Tub MOLD DESIGN in STEP format for just US$35 available for immediate download.

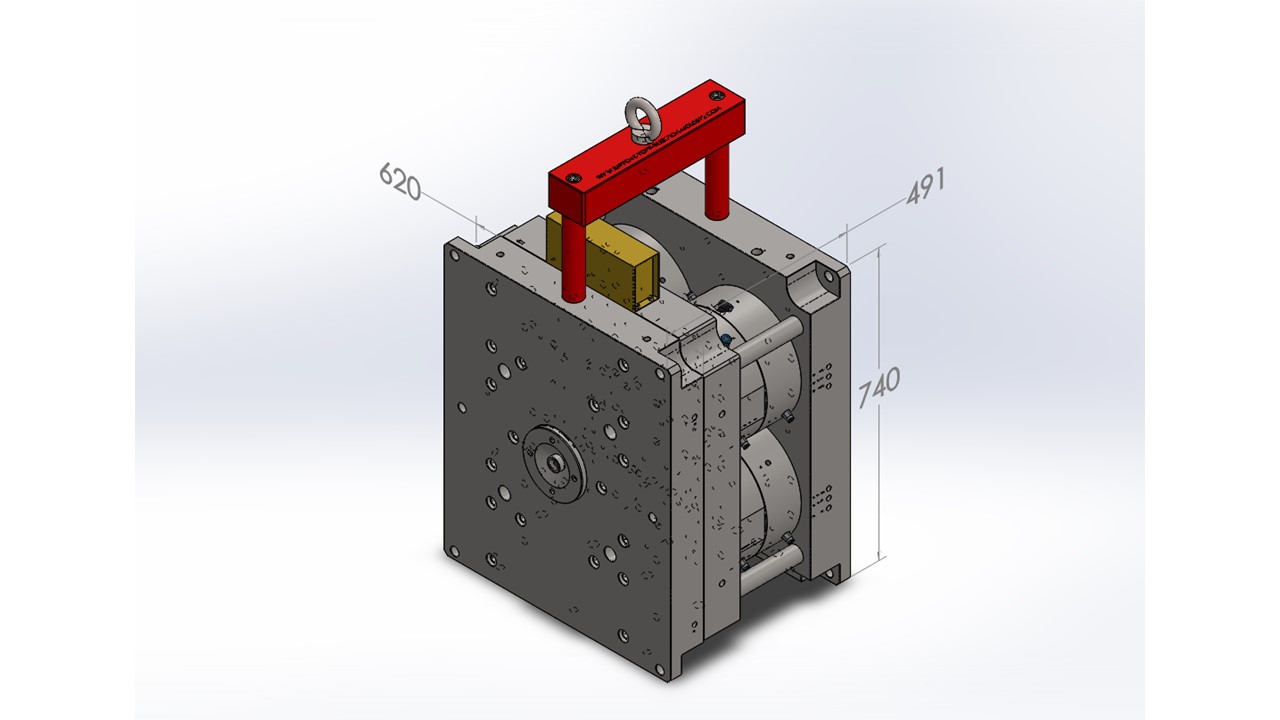

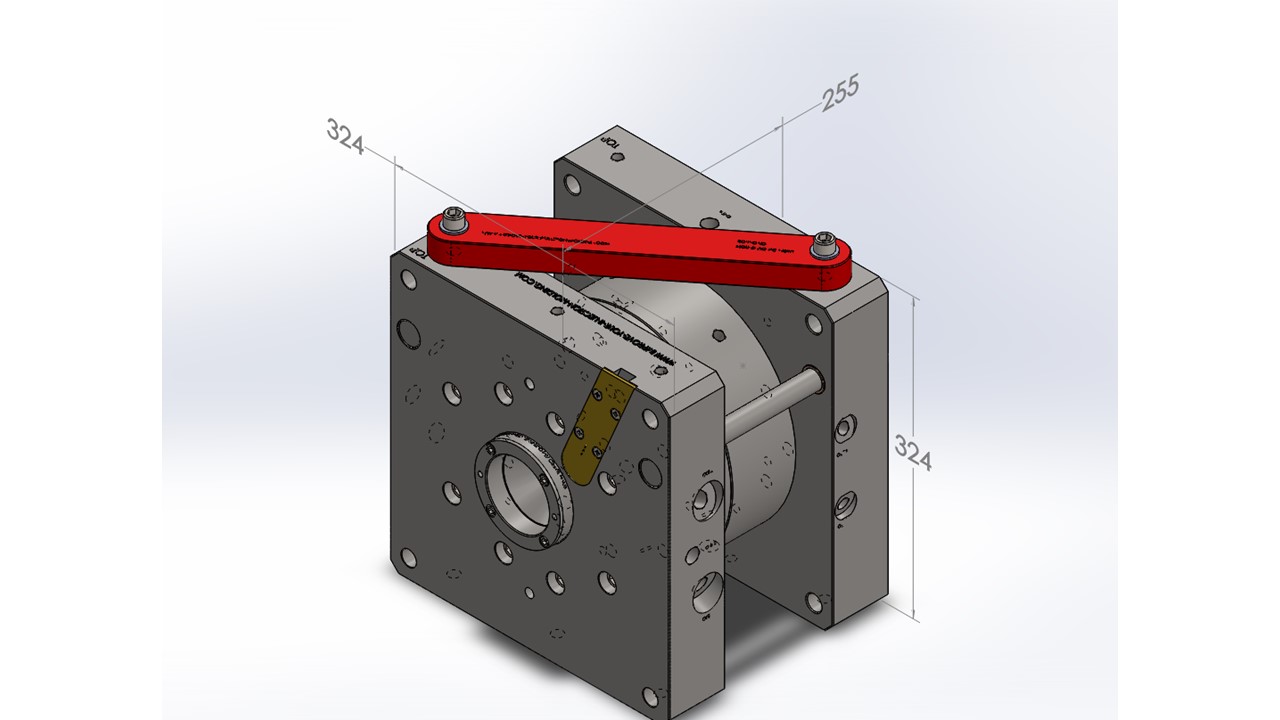

Design D

FOR SALE

4 Cavity Mold Design for the

Common Round Disposable Lid

Common Round Disposable Lid

Common Round Disposable Lid 4 Cavity Round Lid Mold Design For Sale

4 Cavity Round Lid Mold Design For SaleDetails

Lid suits 500 round tub

Weight 6.3 Grams

Wall thickness 0.45mm or less. Nominate your wall thickness, for example 0.38mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 3.5-4.0 seconds (free drop)

Mould designed for 280 ton Sumitomo Demag high speed moulding machine

Annual product capability:31 million (Based on 23hrs/day)

Mold designed with:

1. In House Hot Tip Hot Runner System (can be made by you)

2. Simple assembly techniques

3. Easy mold maintenance procedures

Buy Now

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 4 CAVITY Common Round Lid Tub MOLD DESIGN in Parasolid and STEP format for just US$60 available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.

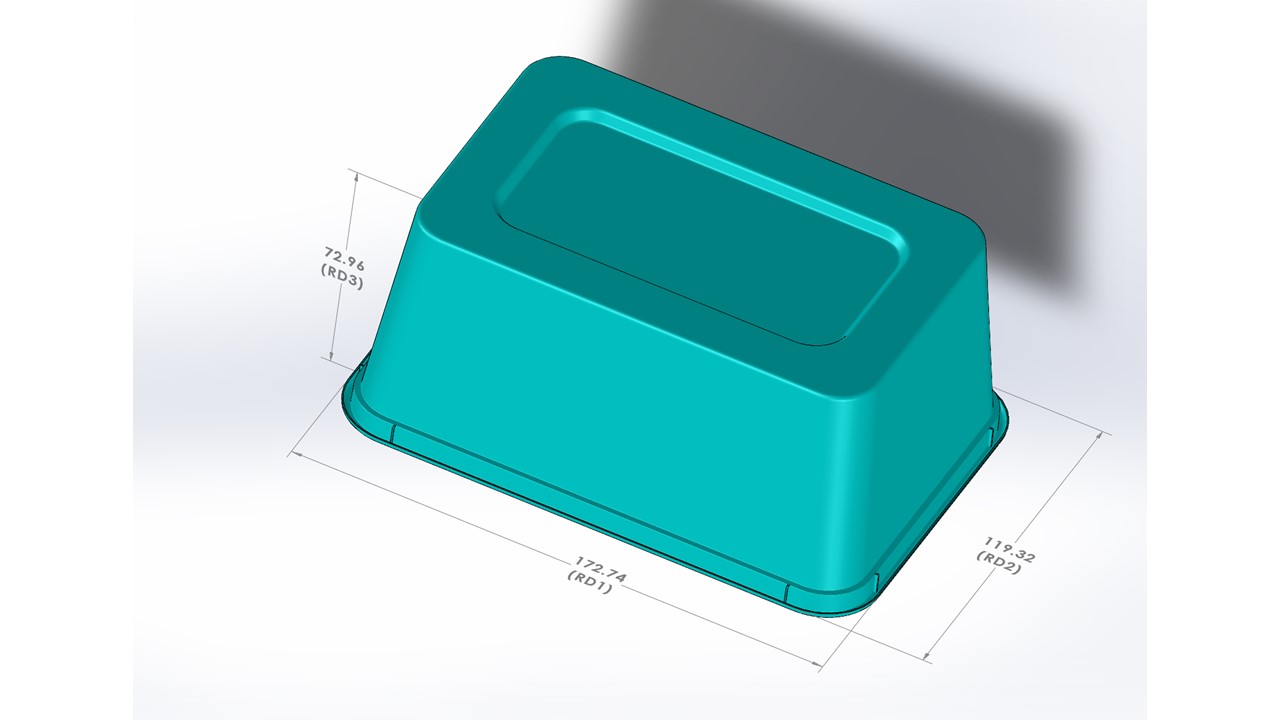

Design E

FOR SALE

1 Cavity Mold Design for the

1000ml Rectangular Disposable Food Tub

CURRENTLY DISCOUNTED

Note: downloaded files password locked so contact me to get password after payment.

Details

Weight 23.1 Grams

Wall thickness 0.46mm

Material: PP (homopolymer)

Cycle time: 3.5-4.0 seconds (free drop)

Designed for Yudo Hot Runner

Mould design suitable for robot takeout (vertical or side entry)

Mould designed for 160 ton Sumitomo Demag high speed moulding machine

Annual product capability: 7 million (Based on 23hrs/day)

Mold designed with:

1. Valve gate allowing easier process control

2. Stripper plate allowing machine ejector movement for consistent ejection & short cycle time

3. Simple assembly

4. Easy mold maintenance

Buy Now!

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 1000ml RECTANGULAR TUB MOULD DESIGN in SOLIDWORKS & PARASOLID format for just $US25 available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.

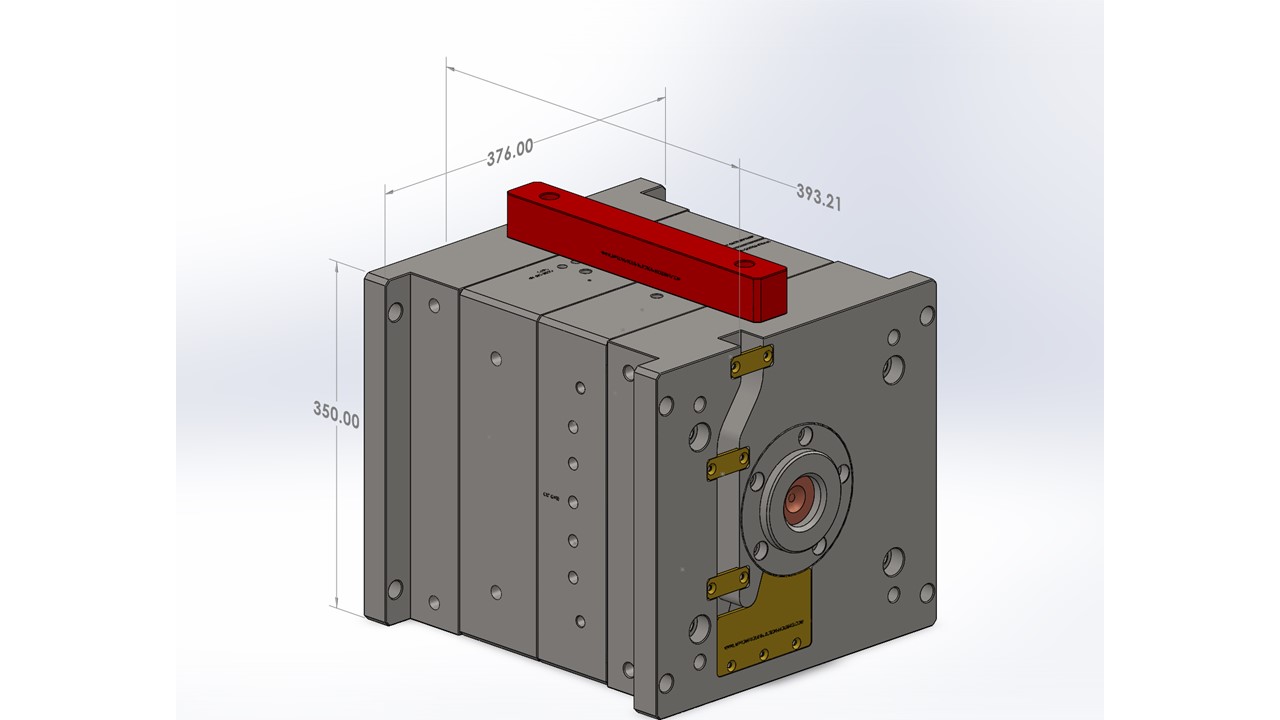

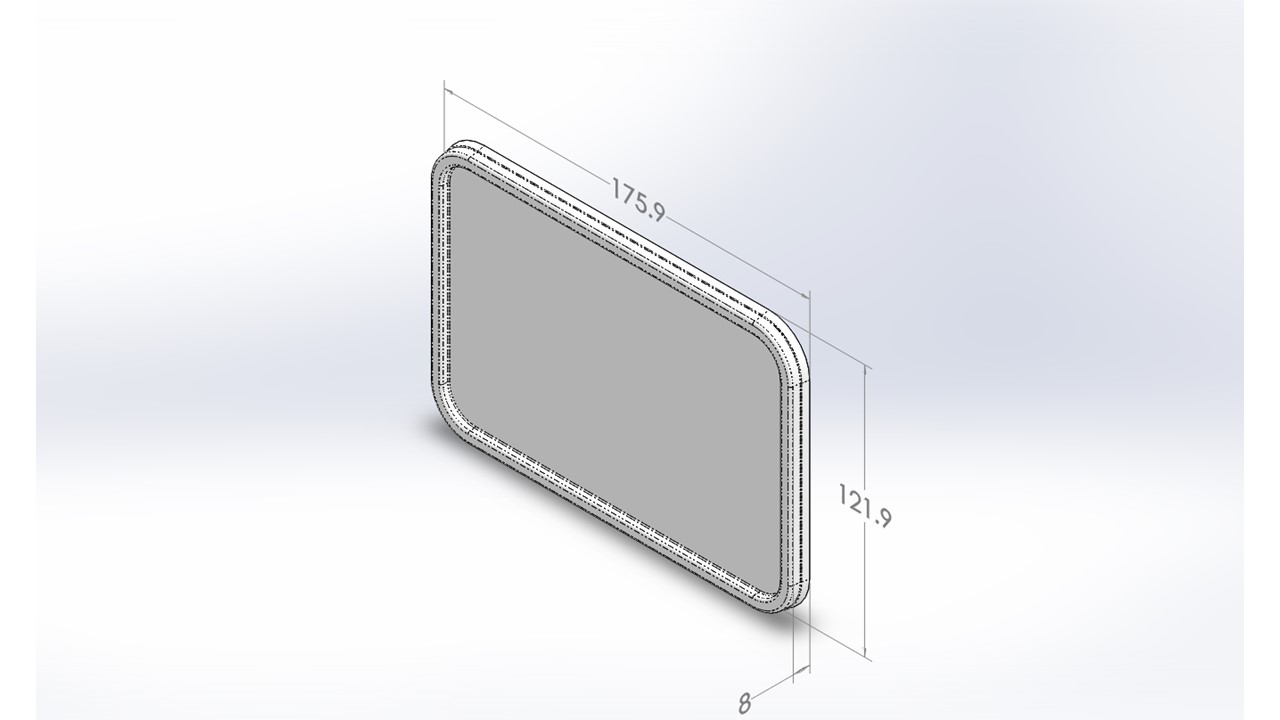

Design F

FOR SALE

1 Cavity Mold Design for the

Rectangular Disposable Food Lid

(To suit 1000ml tub single cavity)

CURRENTLY DISCOUNTED

Note: downloaded files password locked so contact me to get password after payment.

Details

Weight 11.0 Grams

Wall thickness 0.43mm

Material: PP (homopolymer)

Cycle time: 3.0-3.5 seconds (free drop)

Designed for Yudo Hot Runner

Mould design suitable for robot takeout (vertical or side entry)

Mould designed for 160 ton Sumitomo Demag high speed moulding machine

Annual product capability: 9 million (Based on 23hrs/day)

Mold designed with:

1. Valve gate allowing easier process control

2. Stripper plate allowing machine ejector movement for consistent ejection & short cycle time

3. Simple assembly

4. Easy mold maintenance

5. Lid suits single cavity 1000ml rectangular tub mould listed above

Buy Now!

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete RECTANGULAR LID MOULD DESIGN in SOLIDWORKS & PARASOLID format for just US$20 available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.

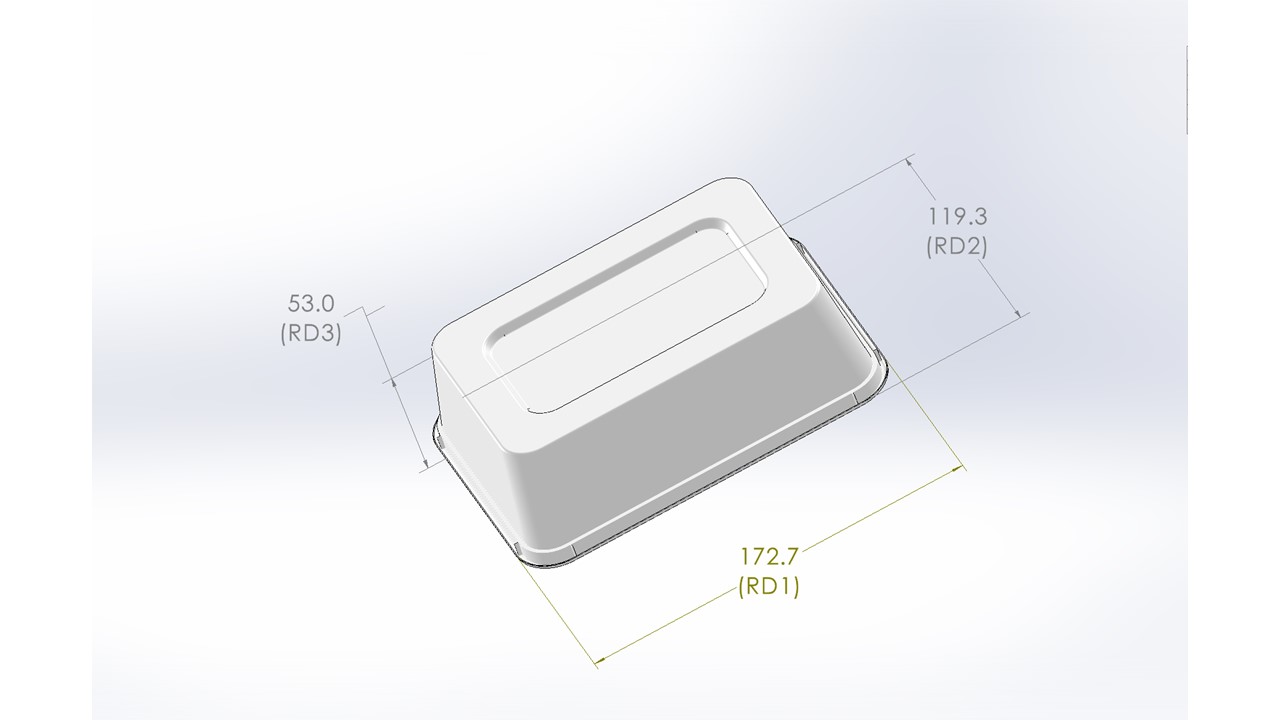

Design G

FOR SALE

2 Cavity Mold Design for the

500ml Rectangular Disposable Food Tub

CURRENTLY DISCOUNTED

500ml Thinwall Disposable Food Tub 16.5 Grams

500ml Thinwall Disposable Food Tub 16.5 Grams

The 2 Cavity Mold in Production

4.1 seconds

Details

Weight 16.5 Grams

Wall thickness 0.45 sides -0.50mm base. Can be less. Nominate your wall thickness, for example 0.40mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 4.0-4.5 seconds (free drop)

Designed for Husky Hot Runner

Mould design suitable for robot takeout (vertical or side entry)

Mould designed for 250 ton El-Exis Demag high speed moulding machine

Annual product capability: 14 million (Based on 23hrs/day)

Mold designed with:

1. Valve gate allowing easier process control (Made by Husky)

2. Stripper plate allowing machine ejector movement for consistent ejection & short cycle time

3. Simple assembly

4. Easy mold maintenance

Buy Now!

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 2 CAVITY 500ml Food Tub MOLD DESIGN in STEP format for just US$35 (was $US399) available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.

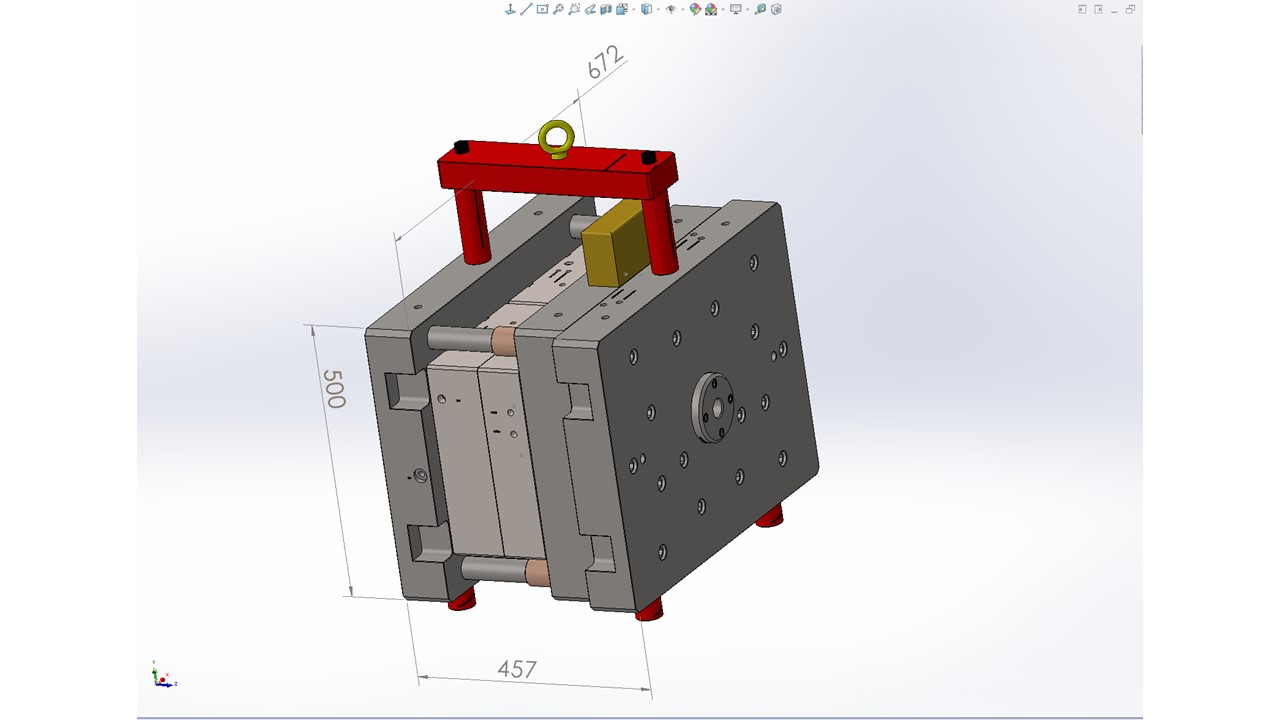

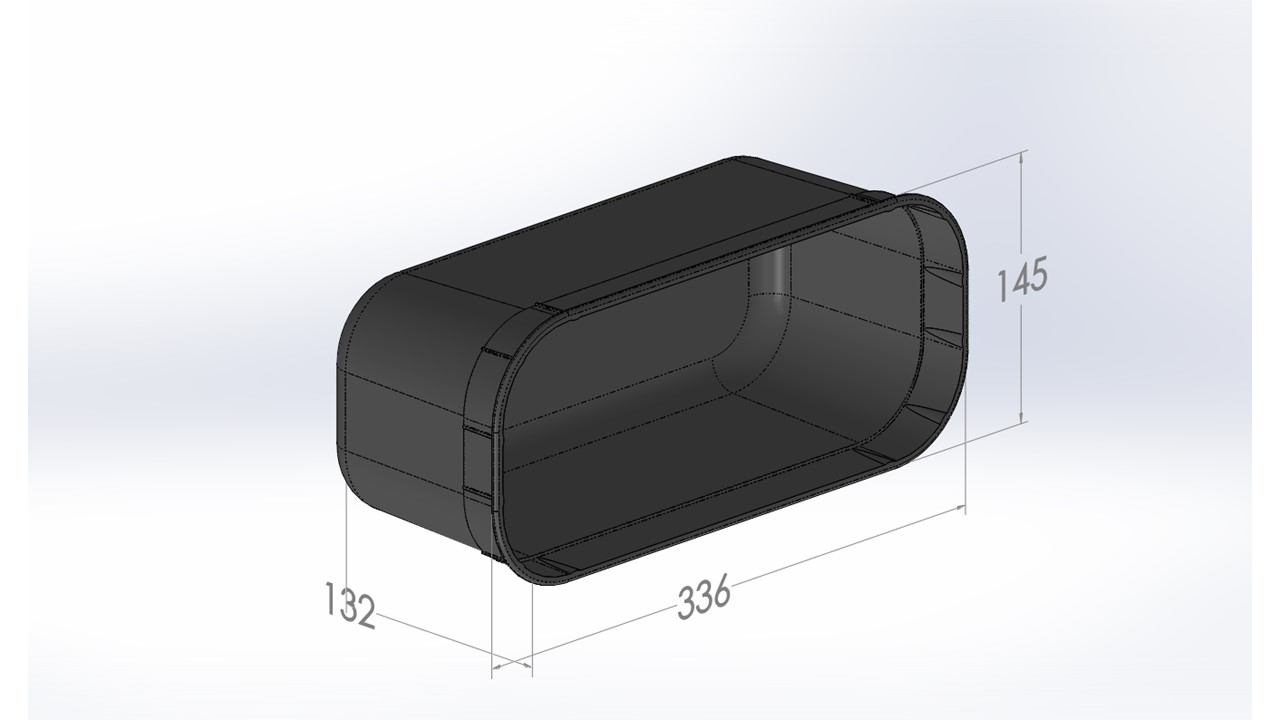

Design G2

FOR SALE

2 Cavity Mold Design for the

750ml Rectangular Disposable Food Tub

750ml Thinwall Disposable Food Tub 18.5 Grams

750ml Thinwall Disposable Food Tub 18.5 Grams 2 cavity mould design for sale 750ml tub

2 cavity mould design for sale 750ml tubDetails

Weight 18.5 Grams

Wall thickness 0.45. Can be less. Nominate your wall thickness, for example 0.40mm Contact us here to change your wall thickness for free to suit your part weight

Material: PP (homopolymer)

Cycle time: 4.0-4.5 seconds (free drop)

Designed for Husky Hot Runner

Mould design suitable for robot takeout (vertical or side entry)

Mould designed for 250 ton El-Exis Demag high speed moulding machine

Annual product capability: 14 million (Based on 23hrs/day)

Mold designed with:

1. Valve gate allowing easier process control (Made by Husky)

2. Stripper plate allowing machine ejector movement for consistent ejection & short cycle time

3. Simple assembly

4. Easy mold maintenance

Buy Now!

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 2 CAVITY 750ml Food Tub MOLD DESIGN in STEP format for just $US450

Note: downloaded files password locked so contact me to get password after payment.

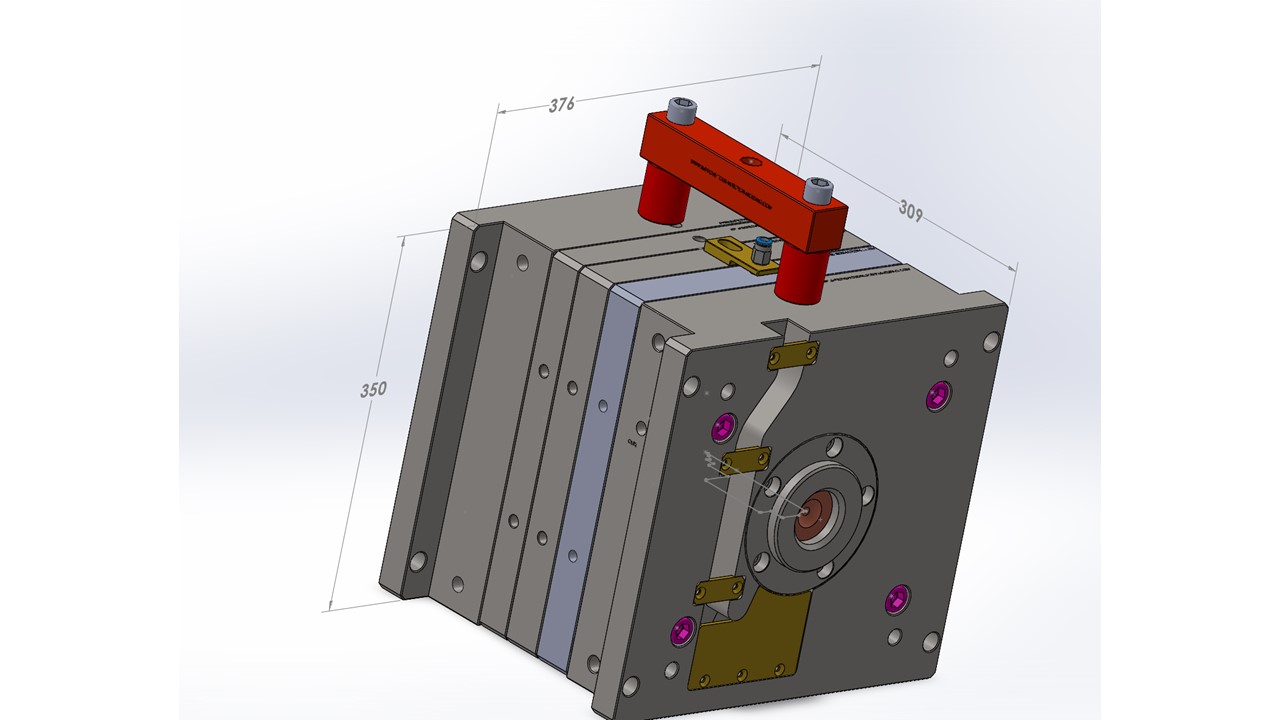

Design H

FOR SALE

4 Cavity Mold Design for the

Rectangular Disposable Food Lid

Thinwall Disposable Food Lid

11.2 Grams

Thinwall Disposable Food Lid

11.2 Grams 4 Cavity Mold Design for Thinwall Disposable Food Lid For Sale

4 Cavity Mold Design for Thinwall Disposable Food Lid For SaleThere is not a video available for this particular part but you can view the same mold design of a 4 cavity thin wall square lid on my You Tube channel by clicking on the link (opens in a new window)

And yes that is me in the video..

Details

Part weight: 11.6 grams

Lid to the fit 500ml food Tub 2 cavity mould

Wall thickness 0.45mm or less. Nominate your wall thickness, for example 0.40mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 3.5-4.0 seconds (free drop)

Designed for Husky Hot Runner

Mold design suitable for robot takeout (vertical or side entry)

Mold designed for 420 ton El-Exis Demag high speed moulding machine

Annual product capability: 30 million (Based on 23hrs/day)

Mold designed with:

1. Valve gate allowing easier process control (Made by Husky)

2. Stripper plate allowing machine ejector movement for consistent ejection & short cycle time

3. Simple assembly

4. Easy mold maintenance

Buy now

Use PayPal or Credit Card

Note: downloaded files password locked so contact me to get password after payment.

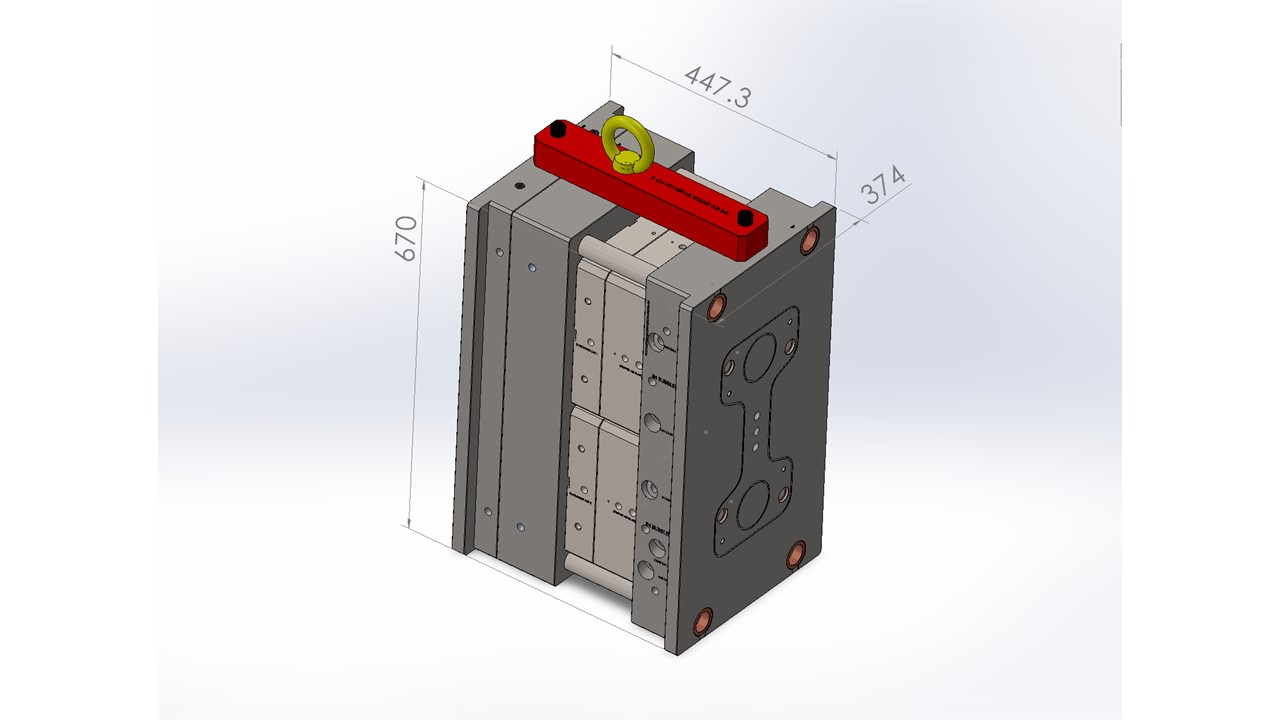

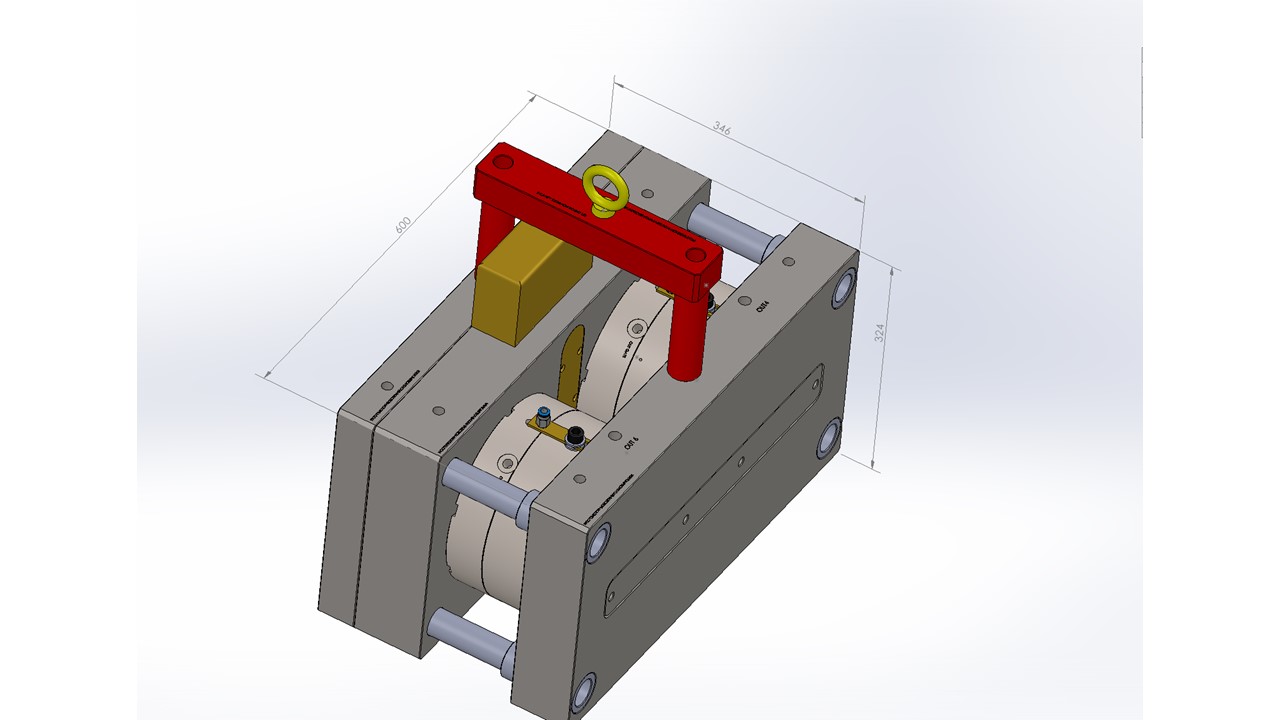

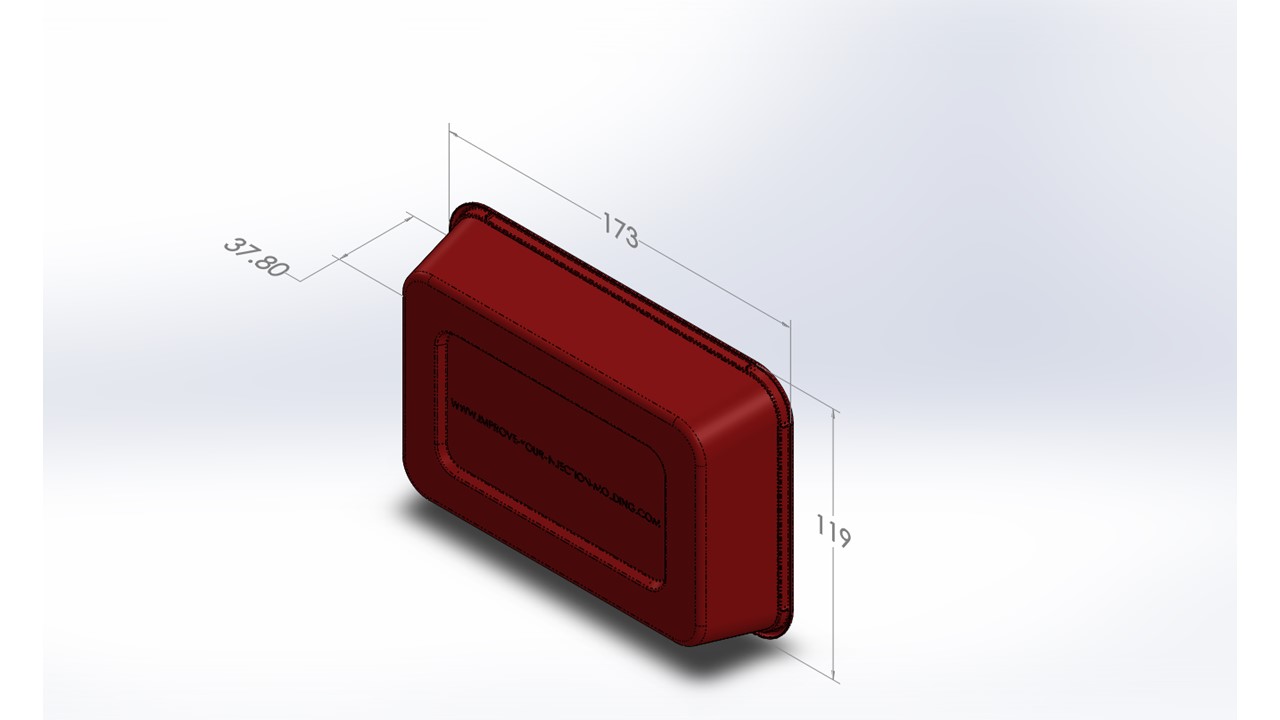

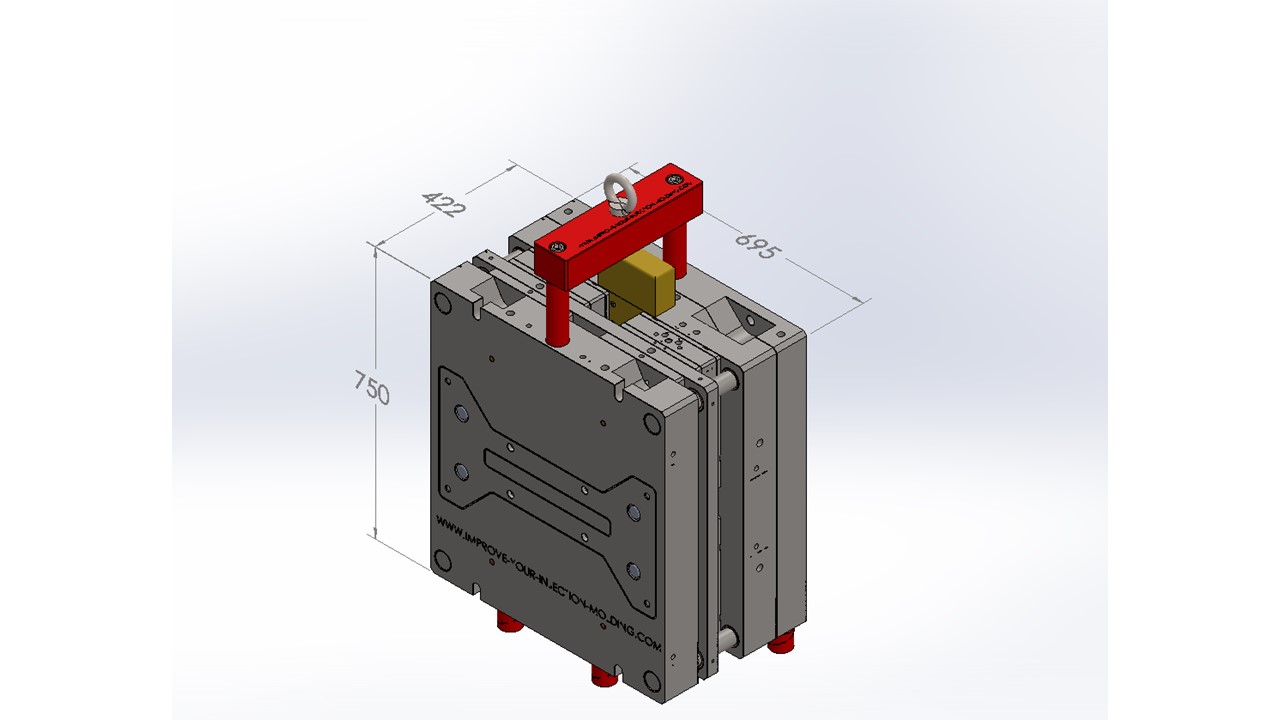

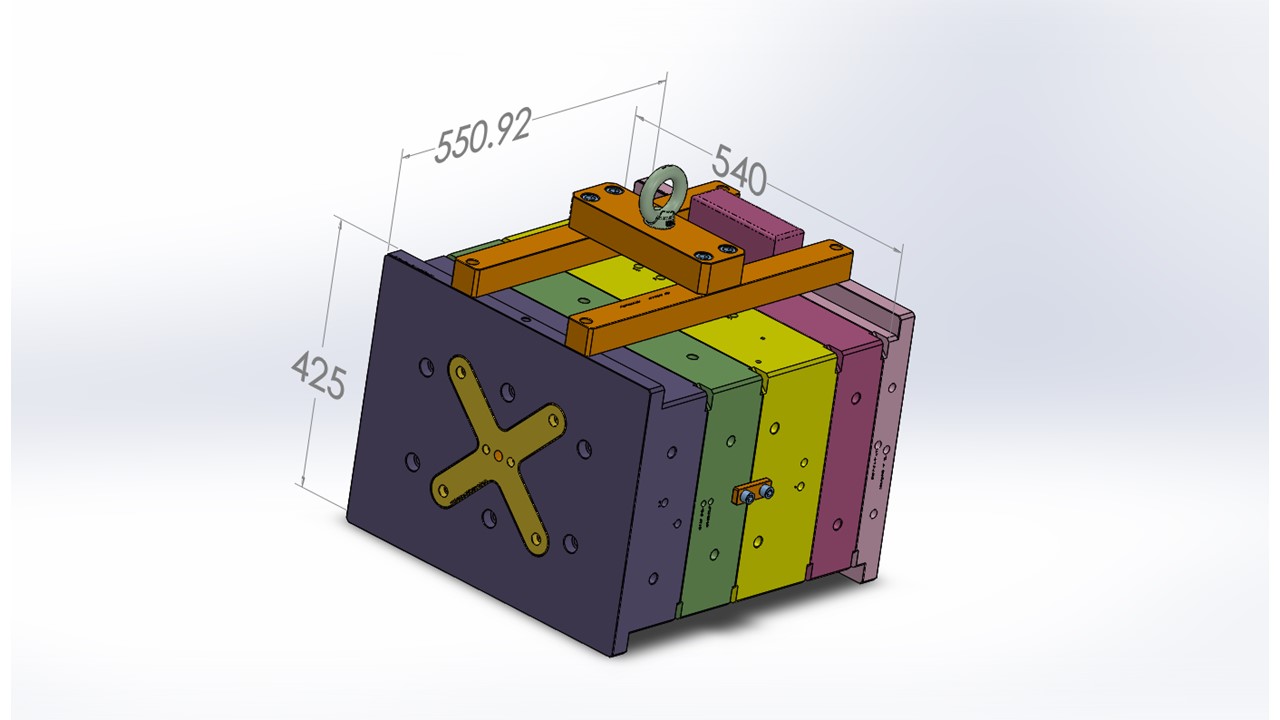

Design I

FOR SALE

2+2 Stack Mold Design for the

Rectangular Disposable Food Lid Currently Discounted

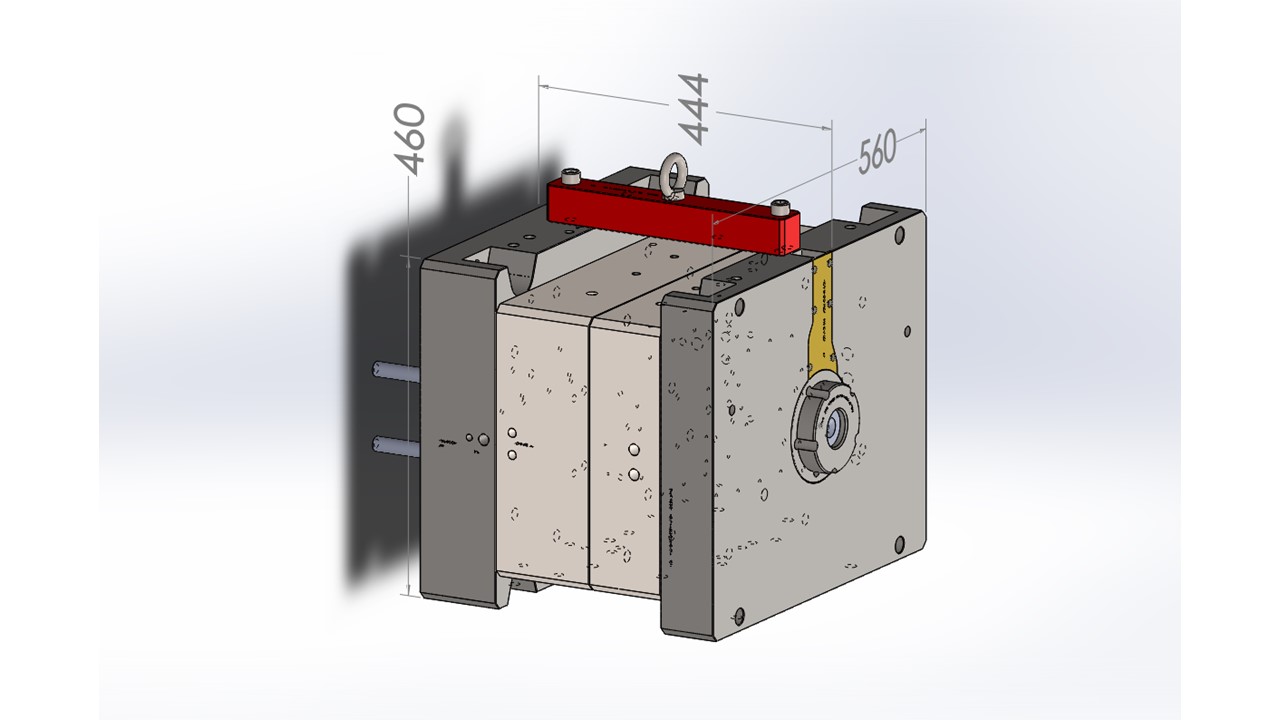

2+2 STACK MOULD DESIGN FOR RECTANGULAR FOOD LID

2+2 STACK MOULD DESIGN FOR RECTANGULAR FOOD LIDDetails

Part weight: 11.2 grams

Lid to the fit 500ml food Tub 2 cavity mould

Wall thickness 0.45mm or less. Nominate your wall thickness, for example 0.40mm Contact us here to change your wall thickness for free.

Material: PP (homopolymer)

Cycle time: 3.0-3.5 seconds (free drop)

Mold designed for 280 ton Sumitomo Demag high speed moulding machine

Annual product capability: 30 million (Based on 23hrs/day)

Mold designed with:

1. Hot tip hot runner

2. Hydraulic stripper plate movement

3. Simple assembly

4. Easy mold maintenance

Buy Now

Use PayPal or Credit Card

Click the PayPal link to purchase & download the complete 2+2 STACK MOLD LID MOULD DESIGN in STEP & PARASOLID format for just US$490 normally US$1550 available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.

Design J

FOR SALE

Single Cavity Mold Design for the

5 Litre Ice Cream Tub

5 LITRE ICE CREAM TUB

5 LITRE ICE CREAM TUB 5 LITRE ICE CREAM TUB MOULD DESIGN

5 LITRE ICE CREAM TUB MOULD DESIGNDetails

Part weight: 99 grams

Wall thickness 0.75mm

Material: PP

Mold designed for 280 ton Sumitomo Demag high speed moulding machine

Mold designed with:

1. Hot tip hot runner (Twin Gate Design)

2. Hydraulic stripper plate movement

3. Simple assembly

4. Easy mold maintenance

Buy Now

Use PayPal or Credit Card

Click here to purchase the complete 5 LITRE TUB MOULD DESIGN in STEP & PARASOLID format for just US$1150 available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.

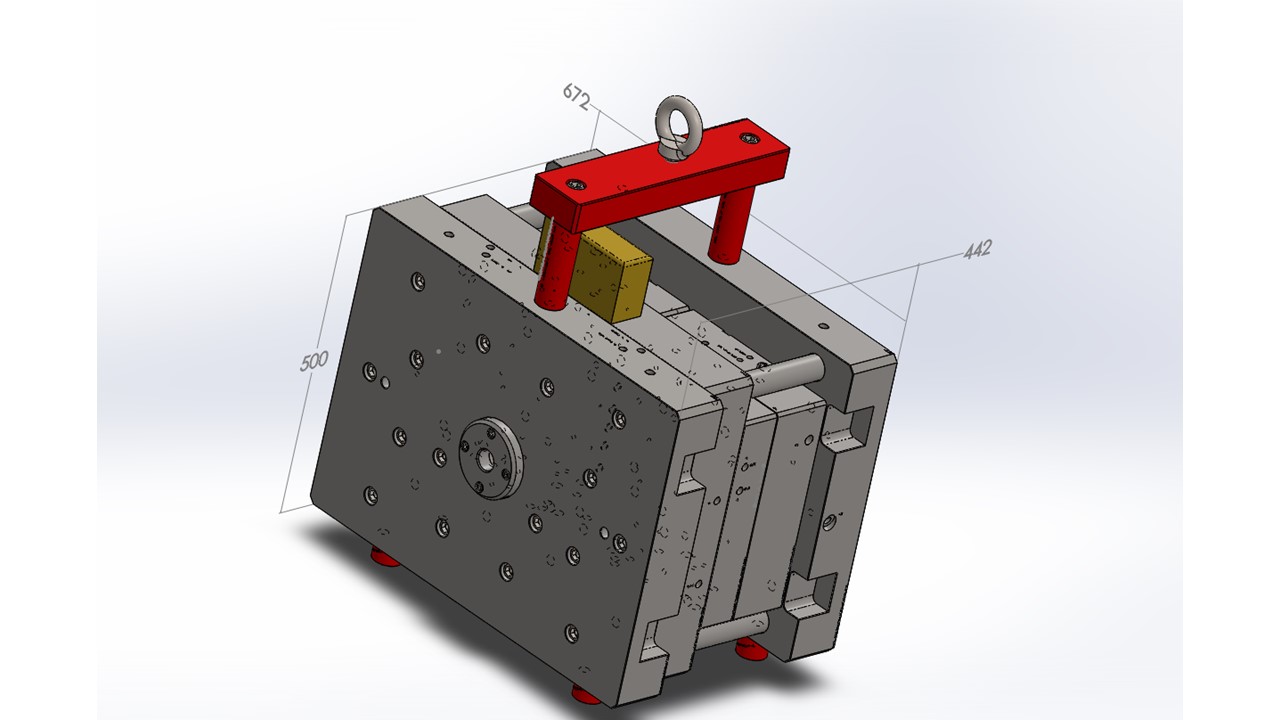

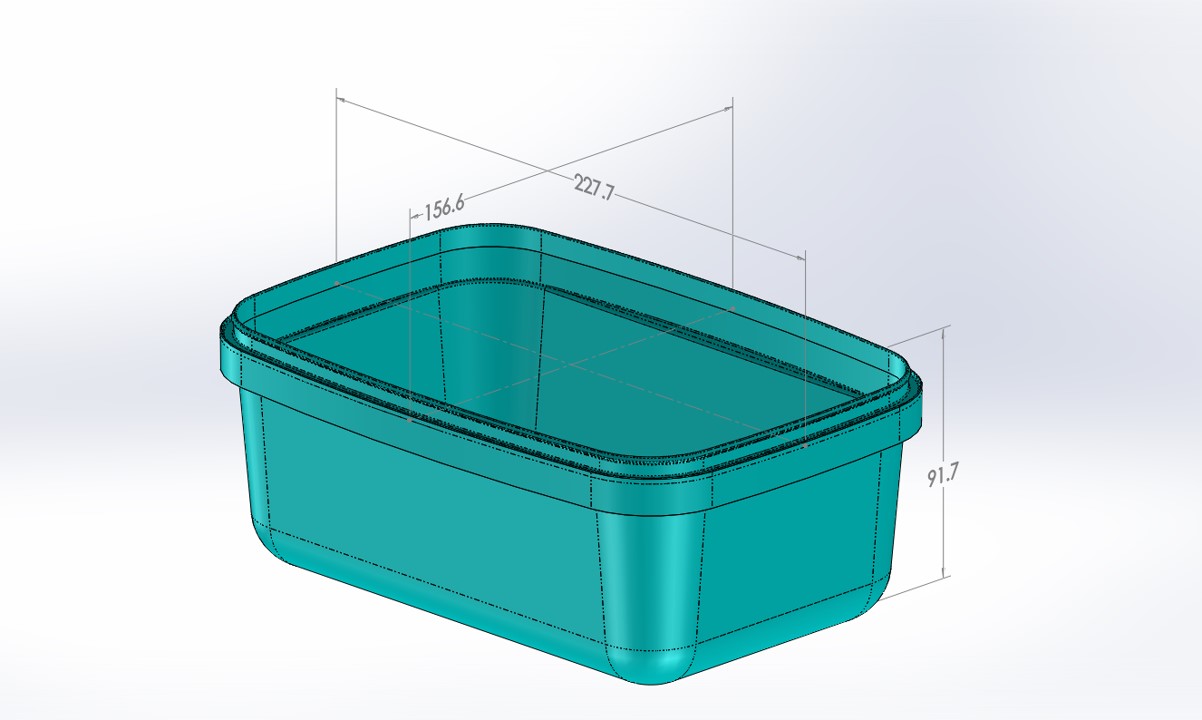

Design K

FOR SALE

Single Cavity Mold Design for the

2 Litre Rectangular Ice Cream Tub (Non-Tamper Evident)

2 LITRE ICE CREAM TUB

2 LITRE ICE CREAM TUB 2 LITRE ICE CREAM TUB MOULD DESIGN

2 LITRE ICE CREAM TUB MOULD DESIGNDetails

Part weight: 64 grams

Wall thickness 0.75mm

Material: PP (copolymer)

Cycle time estimate: 4-5 seconds (free drop)

Designed for Valve Gate Hot Runner

Mold design suitable for robot takeout (vertical or side entry)

Mold designed for 210 ton Sumitomo Demag high speed moulding machine

Annual product capability: 5.5 million (Based on 23hrs/day)

Mold designed with:

1. Valve gate allowing easier process control

2. Two stage ejection

3. Simple assembly

4. Easy mold maintenance

Buy Now

Use PayPal or Credit Card

Click here to purchase the complete 2 LITRE TUB MOULD DESIGN in STEP & PARASOLID format for just US$550 available for immediate download.

Note: downloaded files password locked so contact me to get password after payment.