- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

Choosing a Good Plastic Injection Mould Maker – What To Look For

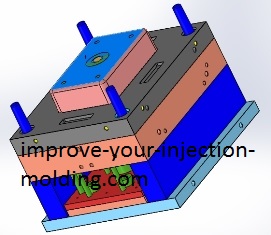

At the heart of any injection molding operation is the plastic injection mould. A good mold maker will make a mould that produces quality parts.

As an injection molder one of your priorities should be to find a mold maker who actually wants to make a difference to your productivity.

There are several benefits to this:

- Faster cycle times

- Lower costs

- Fewer rejects

- Ability to meet deadline

- Higher morale among employees

- Better working relationships

When sourcing a plastic injection mould maker there are a number of things to consider.

The Right Approach

Being a plastic injection mould maker today means more than just cutting steel.

A plastic mold maker should support his injection molding customer from the beginning of a new part concept right through to mass production of the parts especially when trying to reduce cycle times by using aluminium moulds. Click here to find out more about aluminium moulds.

The mold maker should know what questions to ask and be on the lookout for part design issues that could make molding and mold construction difficult.

Changes made at the early stages could save the molder thousands of dollars in waste in terms of rejects and slow cycle times.

This means the molder can make more money, get the jobs completed sooner and won’t suffer the stress and headaches associated with poor decision making that often happen at the start of a product development cycle.

The plastic mold maker should also be present during mould commissioning. Most often new moulds have not been tested in a production environment and they will usually have some minor issues that relate to mold manufacture. The mold maker needs to see the effect on production and discuss with the molder the best way to fix it.

Another reason why a mold maker should be present during commissioning is to ensure water circuits are connected correctly. Water circuits must not be looped as this can cause part quality problems such as warpage.

Having a mold maker with the right approach is critically important when making tight toleranced molds such as stack molds.The mold maker needs to be able to communicate the benefits of stack molds and dispel misconceptions.

Click here to find out more about stack molds

What's more, if you are thinking about buying used plastic injection molds, then a good mould maker should also be able to advise you on the current condition before purchase. Used molds often need repair work in order to produce quality parts. In this way, any potential repair costs are known before buying.

Click here to get your 9-Step Guide to buying Quality Used Plastic Injection Molds

How Does a Plastic Injection Mould Maker Get The Right Approach?

He starts by taking the time to learn about processing and to understand the daily issues that molders face such as hot runner mold problems. Click here to find out more about hot runner molds. When these issues are understood by the mold maker he will naturally look out for potential molding problems stemming from poor part and mold design before cutting steel.

This can only strengthen the relationship and communicate commitment to the success of molding projects.

Pricing

Mould price is usually the first consideration in any new project and for good reason. The lower the price the quicker the payback period which means you can start making a profit sooner.

However, be careful, as there are hidden costs associated with buying a cheap injection mold – especially from Low Cost Countries (LCC).

The price of molds from LCC's can be as much as 70% lower than molds made in western countries such as Australia.

Initially this might seem very attractive but the real cost should be calculated over a period of time in which case you will likely find that there were no savings at all.

Click here to find out why you might be paying too much for injection molds.

In fact it probably cost you money due to ongoing quality issues and slow cycle time.

A common story in Australia is where injection molders will buy cheap new moulds from a LCC only to find one or more of the following issues:

- Slow cycle time

- Poor part quality

- Constant production stoppages due to ejection difficulties

These issues require constant attention so any cost savings on the initial purchase price are quickly eliminated.

So in the end you get what you pay for.

There are many good plastic injection mould makers in LCC's, just make sure you spend time to find the right one for you.

Balance price with quality. Do your research and pay a bit more to get a mould that will produce quality plastic parts consistently.

Click here to find out how to source quality mold manufacturers from China

Delivery

Delivery lead time is critical to getting parts to market on time. When the mold is delivered on time the molder can start making money and satisfy customer’s production requirements.

There is no pressure associated with late deliveries because there are no customers demanding parts that you don’t have.

A good plastic injection mould maker will be able to meet all deadlines regardless of his work load if he has proper leadership and management.

Mold Reliability

If a mold maker can build a mold with the correct materials, heat treatments, corrosion protection and machining tolerances then it will work flawlessly for its intended life provided it is properly maintained. Click here to read about the different types of corrosion resistant techniques available for injection moulds.

The mould should produce quality parts at the correct cycle time without interruptions due to ejection difficulties.

There should be no need for a molder to spend time, energy or money trouble shooting and repairing a mold. Employees should be free to work on the more important money making tasks.

Part design, part material selection, mold design, processing and mold making techniques must all be taken into consideration when making a mould that will be reliable.

That's why constant communication between molder and mold maker is critical to success.

Return from Plastic Injection Mould Maker to Improve Your Injection Molding Home Page