- Home

- Lean Principles

- Machine Selection

- Mold Design

- Mold Interlocking

- Mold Making

- Plastic Material Technology

- Molding Process

- Plastic News

- What's New

- Privacy Policy

- Disclaimer

- Site Map

- Poll

- Polishing

- 3D Rapid Prototyping

- Molding Companies

- Contact Us

- Proven Thinwall Packaging Mold Designs For Sale

- MOLD WEIGHT CALCULATOR

- HOT RUNNER VERSUS COLD RUNNER

A Nucleating Agent Can Reduce Cycle Time And Improve Part Quality

A nucleating agent is an additive to your raw material that will effectively improve productivity. It will reduce cooling time and help with warpage issues as demonstrated in the real life case study below.

Case Study

Material specifications:

| PART MATERIAL | Polypropylene |

|---|---|

| MATERIAL MANUFACTURER | Lyondellbasell |

| MATERIAL GRADE | Random Copolymer |

| MATERIAL CODE | RP241-R |

| PART NAME | Steri Brush Stand |

| PART WEIGHT | 76.2gram |

| NOMINAL WALL SECTION mm | 2.0 |

Equipment used

- 260 ton Sumitomo hydraulic injection moulding machine

- chiller set at 25 degree celsius

- single cavity mould

| MOULD TYPE | Single cavity |

|---|---|

| MOULD MATERIAL | P20 |

| GATE TYPE | Hot tip |

| EJECTION TYPE | Ejector pins |

| NO. WATER CIRCUITS | 9 |

Step 1.

Using raw PP material, minimized cycle time until part was just within quality limits (size and warpage limits).

| RESULTS | Raw PP |

|---|---|

| CYCLE TIME seconds | 14.4 |

| COOLING TIME seconds | 7.0 |

Step 2.

Added 2% nucleating agent (nanosil)and increased back pressure to aid in mixing during the plasticizing stage. See table below for changes in back pressure:

| PROCESSING PARAMETERS | Step 1 | Step 2 |

|---|---|---|

| BARREL TEMPERTURES ⁰C | 235 230 210 205 | 235 230 210 205 |

| BACK PRESSURE bar | 4 stages 224 224 224 56 | 4 stages 392 392 392 56 |

| INJECTION TIME seconds | 1.0 | 1.0 |

| HOLD TIME seconds | 2 stages 0.8 0.2 | 2 stages 0.8 0.2 |

| HOLD PRESSURE bar | 2 stages 504 420 | 2 stages 504 420 |

Step 3.

Reduced cooling time until part was just within quality limits (size and warpage limits).

| RESULTS | PP with 2% nucleating agent |

|---|---|

| CYCLE TIME seconds | 12.5 |

| COOLING TIME seconds | 5.1 |

Results

The following table shows the difference in cycle time between the raw PP and with 2% addition of the agent:

| RESULTS | Raw PP | PP with 2% nucleating agent |

|---|---|---|

| CYCLE TIME seconds | 14.4 | 12.5 |

| COOLING TIME seconds | 7.0 | 5.1 |

| CYCLE TIME DIFFERENCE seconds | 0 | 1.9 |

| CYCLE TIME DIFFERENCE % | 0 | 13% reduction |

The cycle time was reduced by 13% while maintaining quality. This makes this particular machine 13% more productive which means an extra 912 parts per day(24hr) could be produced.

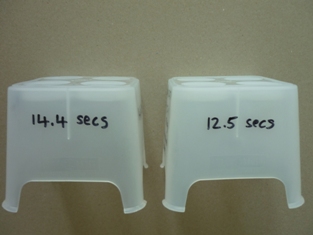

The following photo of the part shows how the quality was maintained even with a shorter cycle time. In fact, even though both parts are within quality limits, the part produced from the shorter cycle time has less distortion than the other part across the top face. The 12.5 secs part is flatter on the top face.

Conclusion.

A 13% reduction in cycle time translates into a large increase in productivity. It is a very easy way to immediately increase productivity but it does come at a cost – the price of the agent.

There are many companies selling nucleating agents for use in injection molding so by shopping around and experimenting with mixing ratios and processing parameters cost can be kept to a minimum.

Return from Nucleating Agent to Plastic Raw Material Technology